The BIOSTAR MS-J6412 and MT PRO-J6412 systems are compact computers expertly engineered for industrial computing needs. They utilize a fanless design that ensures silent operation, dust resistance, and durability. These systems are ideal for various applications such as gateways, POS systems, network communication devices, gate sensors, and IoT systems, offering the benefits of space-saving and low power consumption.

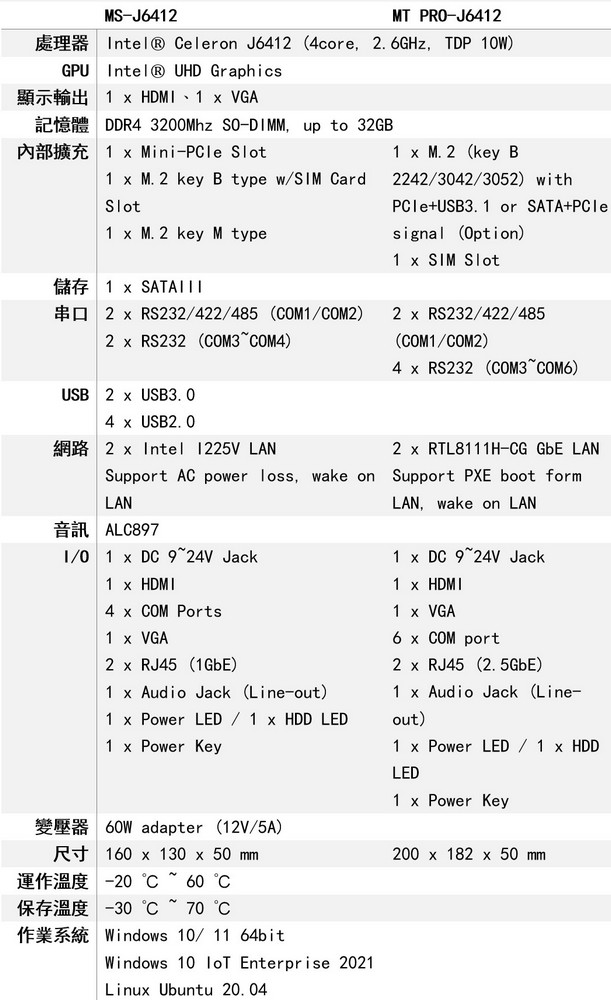

Here’s a quick rundown of their specifications:

- CPU: Intel® Celeron J6412 (4-core, 2.6GHz, TDP 10W)

- GPU: Intel® UHD Graphics

- Memory: DDR4 3200Mhz SO-DIMM, up to 32GB

- Expansion Slots:

- MS-J6412: 1 x Mini-PCIe Slot, 1 x M.2 Key B type w/SIM Card Slot, 1 x M.2 Key M type

- MT PRO-J6412: 2 x M.2 (key B), 1 x USB 3.1 or SATA+PCIe signal, 1 x SIM Slot

- Storage Interface: SATAIII

- Serial Ports: RS232/422/485

- USB Ports: USB 3.0 and USB 2.0

- LAN:

- MS-J6412: 2 x Intel I225V LAN, supporting PXE boot form LAN, wake on LAN

- MT PRO-J6412: 2 x RTL8111H GbE LAN, supporting wake on LAN

- Audio: ALC897

- Power Supply: 60W adapter (12V/5A)

- Dimensions:

- MS-J6412: 160 x 130 x 50 mm

- MT PRO-J6412: 200 x 182 x 50 mm

- Operating Temperature: -20°C to 60°C

- Storage Temperature: -30°C to 70°C

- Supported Operating Systems: Windows 10/11 64bit, Windows 10 IoT Enterprise 2021, Linux Ubuntu 20.04

Both models promise to deliver performance and reliability in demanding industrial environments. Whether it’s for controlling a gateway or integrating into a smart IoT framework, these computers provide a powerful yet energy-efficient solution that can fit into compact spaces without compromising on the computing power needed for robust applications.

Exploring Industrial System Computers from a Gamer’s Perspective: A Performance Comparison of MS-J6412 and MT PRO-J6412

Application system computers are a specific type of computer designed for commercial or industrial environments. Typically equipped with COM serial ports, they connect to various devices including gateways, POS systems, network communication devices, gate sensors, and IoT systems. Since the MS-J6412 and MT PRO-J6412 are readily available on e-commerce platforms, this article will conduct a simple performance and functionality test from a consumer’s perspective. Who knows, you might even be tempted to buy one to experiment with.

Both the MS-J6412 and MT PRO-J6412 models boast the Intel Celeron J6412 processor, featuring 4 cores with a maximum frequency of 2.6GHz and a TDP of only 10W. The key differences between the two computers lie in their expandability. The MT PRO-J6412 is equipped with 6 COM ports and dual 2.5GbE network ports, whereas the MS-J6412 has 4 COM ports and dual 1GbE network ports but is overall more compact.

Regarding display outputs, both models come with an HDMI and a VGA port, with HDMI supporting 4K resolution. VGA is becoming obsolete in the modern display card market due to its analog signal, which requires an additional chip for conversion to a digital signal, although it remains convenient for older equipment.

Neither the MS-J6412 nor the MT PRO-J6412 comes with built-in Wi-Fi or Bluetooth, but they can be easily expanded via the internal M.2 slot or Mini PCIe slot. Additionally, both computers support a physical SIM card, allowing for mobile network connection in environments without Wi-Fi.

The two cardboard boxes are stacked on top of each other, and the BIOSTAR logo is prominently displayed on the top box. This type of packaging is simple and sturdy, fitting the industrial aesthetic, and suggests that the product inside is from BIOSTAR, which is known for its range of computer components and industrial computing systems. The brown color and minimalistic design reflect an eco-friendly and professional approach, which is common for products like motherboards, GPUs, or industrial computers, which the MS-J6412 and MT PRO-J6412 could be part of.

We see the side view of the same cardboard boxes, now showing the text “MADE IN TAIWAN” indicating the country of manufacture. This tagline often signifies quality manufacturing and technological prowess, as Taiwan is renowned for its advanced electronics industry. Additionally, there’s a label with a barcode, model number, and possibly specifications of the product, typical for industrial or technological products ensuring traceability and easy inventory management. This kind of labeling is essential for both logistics and end-users who might be looking for specific information about the product inside the packaging.

There are two stacked heatsinks. The top one is for the MS-J6412 and the bottom one is for the MT PRO-J6412. These heatsinks are an integral part of the fanless design of these industrial computers, used to dissipate heat and keep the system cool without the need for a fan, contributing to the systems’ silent operation, dust resistance, and overall durability. The black fins increase the surface area to facilitate heat transfer to the surrounding air. This design is essential for maintaining optimal performance and reliability, especially in industrial environments where computers may be subject to more rigorous or continuous use.

We see the front I/O (input/output) panels of two compact industrial computers, presumably the MS-J6412 (top) and the MT PRO-J6412 (bottom). They are designed to offer a variety of connectivity options:

The MS-J6412 (top) features:

- Two LAN ports for network connections.

- Four USB ports, a combination of USB 3.0 and 2.0 for peripheral devices.

- VGA and HDMI for display outputs, supporting dual monitors and 4K resolution via HDMI.

- A power button (SW).

The MT PRO-J6412 (bottom) includes:

- A DC-IN for power supply.

- An HDMI and a VGA port for video output.

- One COM port (COM1) for serial devices.

- Multiple USB ports, again, a mix of USB 3.0 and 2.0.

- Two LAN ports for network connections.

- An audio jack for sound output.

- A power button (SW).

These panels reflect the computers’ versatility and capability to connect to various devices, suitable for industrial applications that require multiple connectivity options for monitors, serial devices, and network connections. The presence of both modern (USB 3.0, HDMI) and legacy (VGA, COM port) interfaces indicates that these systems are designed to work with a wide range of equipment, from the latest technology to older, legacy systems.

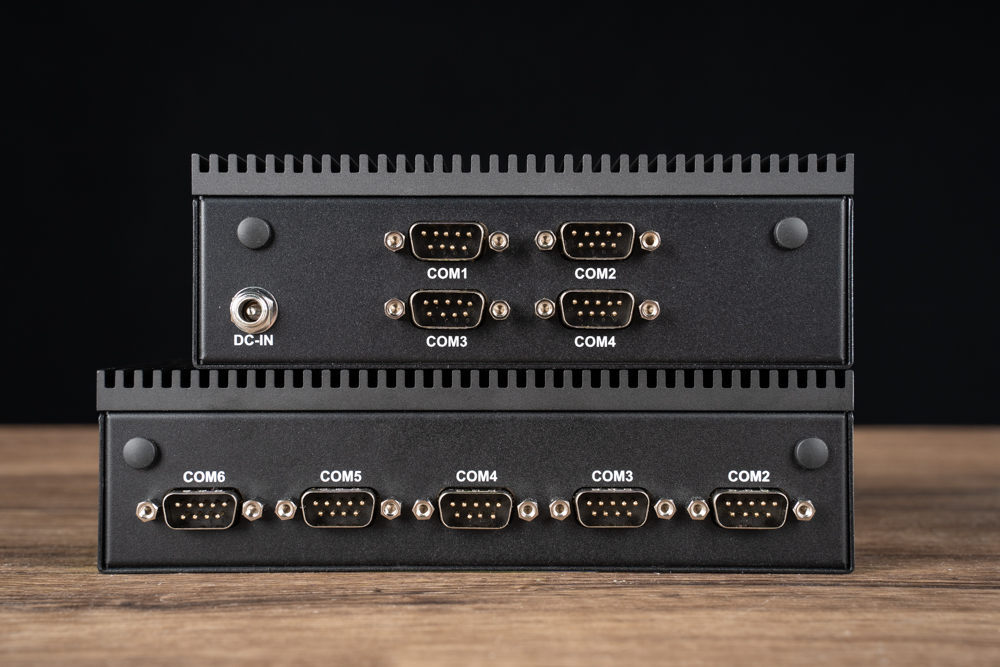

The rear I/O (input/output) panels of the two industrial computers, the MS-J6412 (top) and the MT PRO-J6412 (bottom). Their back panels are dedicated to serial port connectivity, which is essential for industrial applications that require reliable and long-established communication protocols.

The MS-J6412 (top) includes:

- Four COM ports, labeled from COM1 to COM4, used for serial communications with devices such as sensors, modems, and various control systems.

- A DC-IN port for the power supply, to power the unit.

The MT PRO-J6412 (bottom) has an even greater focus on serial connectivity, featuring:

- Six COM ports, labeled from COM2 to COM6. This increased number of COM ports allows for more devices to be connected simultaneously, which is critical for complex industrial setups.

The inclusion of multiple COM ports on both models underlines their industrial-grade capabilities, providing robust options for connecting to various legacy control systems and equipment that still rely on serial communication in industrial, retail, or scientific environments.

The bottom view of one of the industrial computer systems, either the MS-J6412 or the MT PRO-J6412. We can observe that there are no visible mounting holes for wall installation, which indicates that this particular design might not directly support wall mounting out of the box. However, it’s common for such systems to be placed inside enclosures or racks that can be mounted, or to use optional brackets for such installations. The bottom plate appears solid and is secured with screws, which is typical for industrial-grade equipment designed for stability and durability.

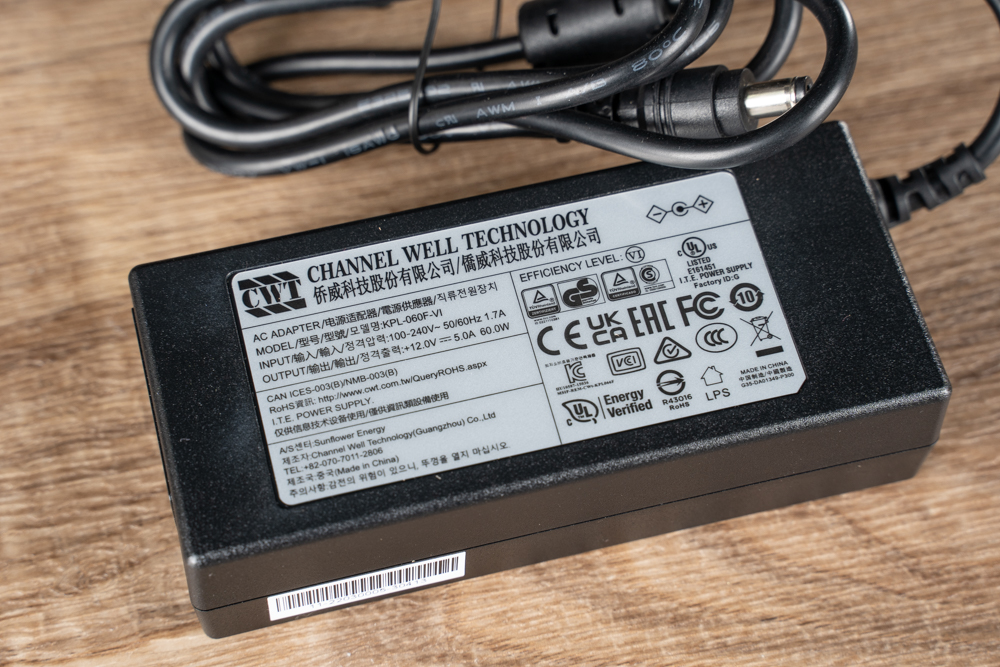

The accessories that come with one of the industrial computer systems. Included in the set is a power adapter, which converts AC to DC power for the device, and four adhesive foot pads. These foot pads can be attached to the bottom of the computer to provide stability and prevent slipping or scratching surfaces where the computer may be placed. The simplicity of the accessories suggests a focus on the fundamental requirements to get the system up and running without unnecessary extras.

A close-up of the power adapter made by Channel Well Technology (CWT), a well-known manufacturer in the power supply industry. The specifications indicate it’s a 60-watt power adapter, which aligns with the requirements for the industrial computers we discussed earlier. The various symbols and certifications on the adapter denote its compliance with international safety and environmental standards, such as CE for European compliance, UL listing for safety, and the Energy Verified mark, which suggests energy efficiency. These certifications are crucial for industrial components, ensuring they meet rigorous standards for safety, reliability, and energy efficiency.

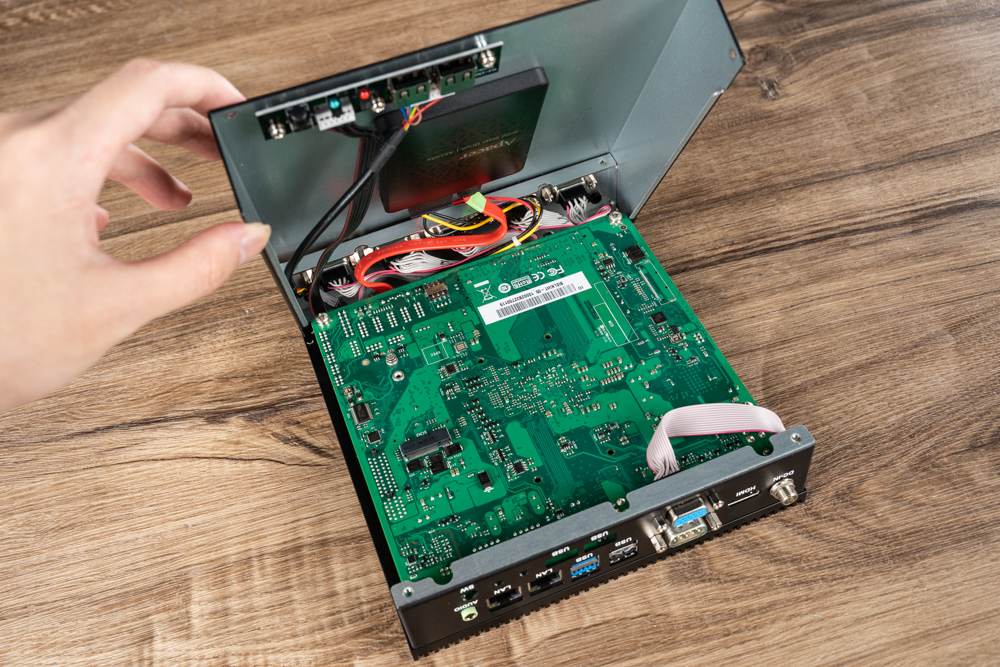

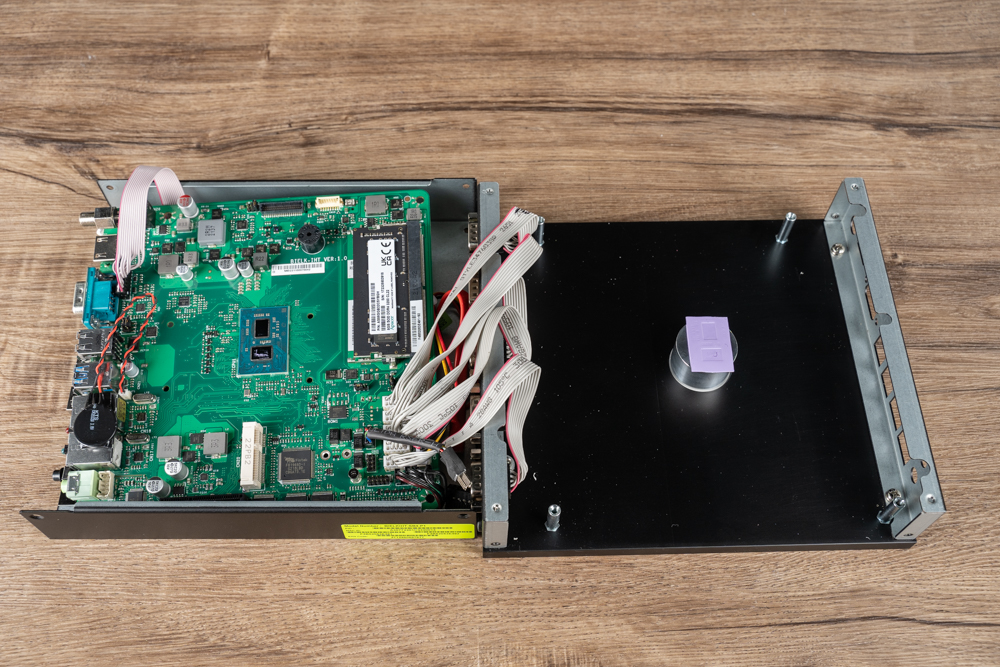

The image illustrates the internal components of what seems to be the MT PRO-J6412 after the removal of the bottom cover, revealing the main circuit board. A person’s hand is shown in the process of opening the unit, with various cables connected between the bottom cover and the motherboard, which users should be cautious of when disassembling to avoid damage.

Key points regarding the internals:

- Motherboard Installation: The motherboard is mounted in an inverted manner. This means that the motherboard needs to be removed for upgrades or installations, such as adding memory or Mini PCIe devices, which can be a bit cumbersome.

- Accessible Components: The SIM card slot, M.2 (key B for sizes 2242/3042/3052), and 2.5-inch SSD storage are accessible and can be replaced or upgraded by simply removing the bottom cover, making these components more user-serviceable.

- Passive Cooling Design: The MT PRO-J6412 uses a passive cooling system, which differs from traditional active cooling systems that utilize fans. The motherboard is attached to the top cover’s heatsink via four screws, ensuring that the heat is transferred effectively to the heatsink without the need for a fan, contributing to the system’s durability and silent operation.

Such design considerations highlight the unit’s suitability for industrial environments where stability, reliability, and easy maintenance are critical. Users should be aware of these details before attempting to service or upgrade the components to ensure they do not damage the system.

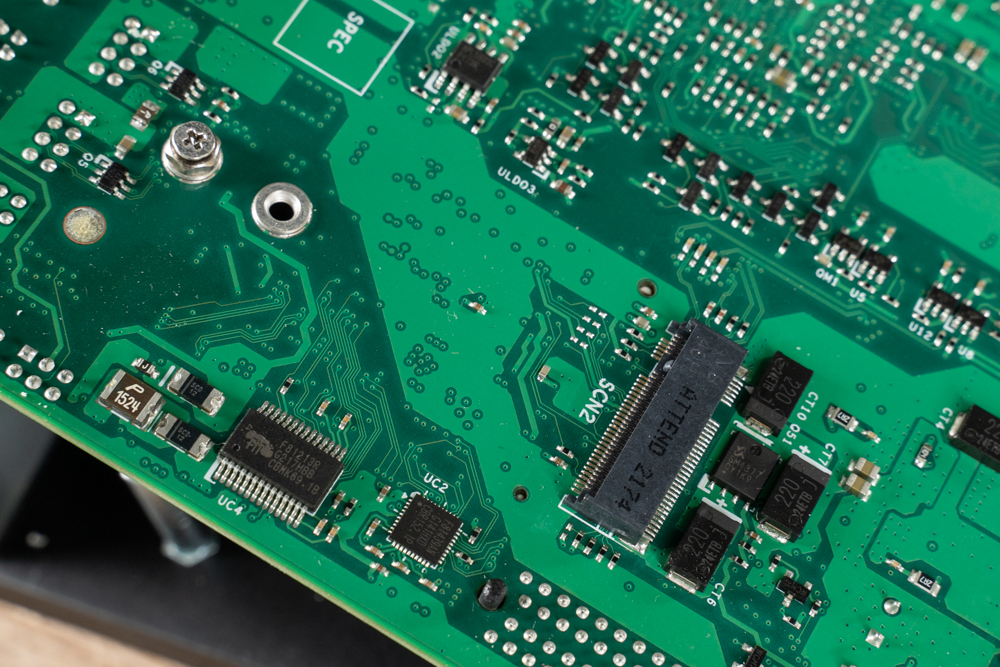

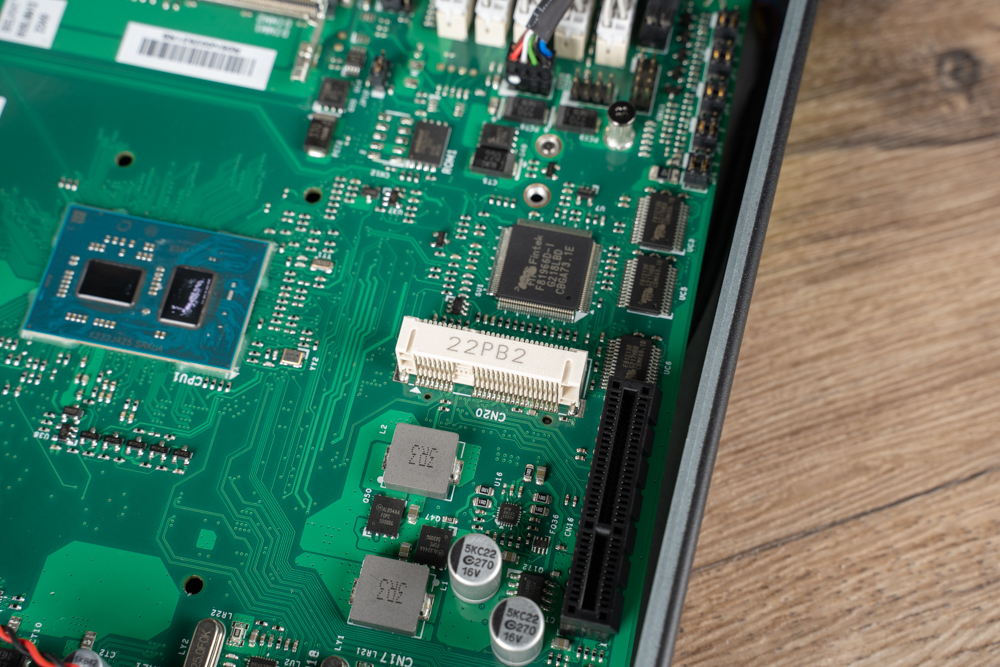

A close-up of the motherboard from one of the industrial computers, highlighting the M.2 slot, which adheres to the B-key specification supporting sizes 2242, 3042, and 3052. This particular keying supports PCIe and USB 3.1 or SATA and PCIe signal lanes as an optional feature, which is not as common as the M-key M.2 slot typically found in consumer PCs that mainly support NVMe SSDs with PCIe lanes for data transfer.

The distinction in key types is significant for compatibility with different M.2 devices. B-key slots often support a broader range of modules, including SSDs, WWAN cards, and other functionality-expanding hardware, making them versatile for the industrial computers’ applications where varied uses might be necessary.

In the industrial computing space, this flexibility is crucial for customization based on specific application requirements, such as adding cellular connectivity or storage that aligns with the user’s needs. The presence of such a slot also allows for easy upgrades and maintenance, which can be an essential factor for the longevity and adaptability of industrial systems.

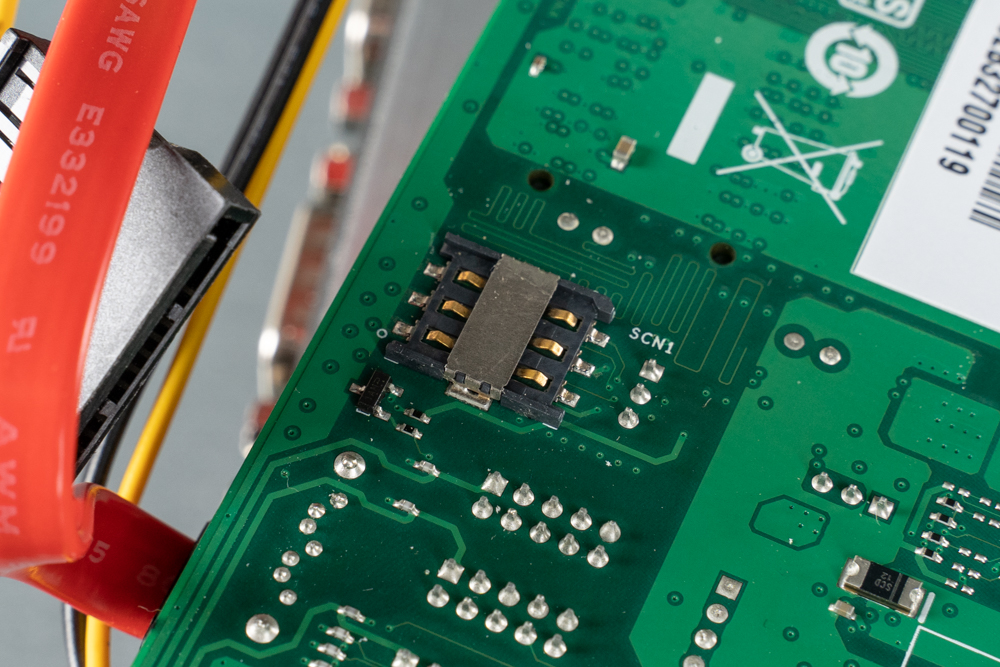

The photograph highlights a section of the motherboard showcasing a SIM card slot, which is typically used to provide cellular network connectivity to a device. This inclusion is particularly important in industrial computers like the MT PRO-J6412, which may need to connect to the internet or other networks in environments where traditional wired or Wi-Fi connections are unavailable or unreliable. The ability to add a SIM card directly into the system’s motherboard allows for integrated mobile network access, ensuring that the computer can connect to 3G, 4G, or even 5G networks, depending on the system’s modem capabilities. This feature is essential for IoT applications, remote monitoring, and control systems that require constant connectivity.

A close-up of the industrial computer’s edge with various connectors, and it illustrates a part of the disassembly process. In order to remove the motherboard, one must first unscrew the retaining screws of the COM ports and the VGA connector. The photograph captures two such screws and their corresponding washers that have been removed, which are typically used to secure these connectors to the case, ensuring a stable and robust connection that can withstand the vibration and movement often encountered in industrial settings. Proper reassembly, with these screws securely fastened, is crucial to maintain the structural integrity and connectivity of the system.

The disassembled state of an industrial computer system, with the motherboard successfully removed from the chassis. Visible is the motherboard itself, which houses various components such as RAM, storage, and expansion slots, as well as the inside of the chassis with its heat sink pad and various interface connectors still attached. The removed screws, which were securing the motherboard to the chassis, are also shown.

The heat sink pad on the inside of the cover indicates that this system uses passive cooling, with the cover acting as a heat sink to dissipate heat away from the motherboard. This type of cooling system is typical in industrial computers due to its reliability and the lack of moving parts, which could be susceptible to failure in challenging environments.

Disassembling such a computer requires careful attention to detail to ensure all connections are properly detached and components are not damaged in the process. The disassembled state provides an opportunity for upgrades, repairs, or maintenance tasks to be performed.

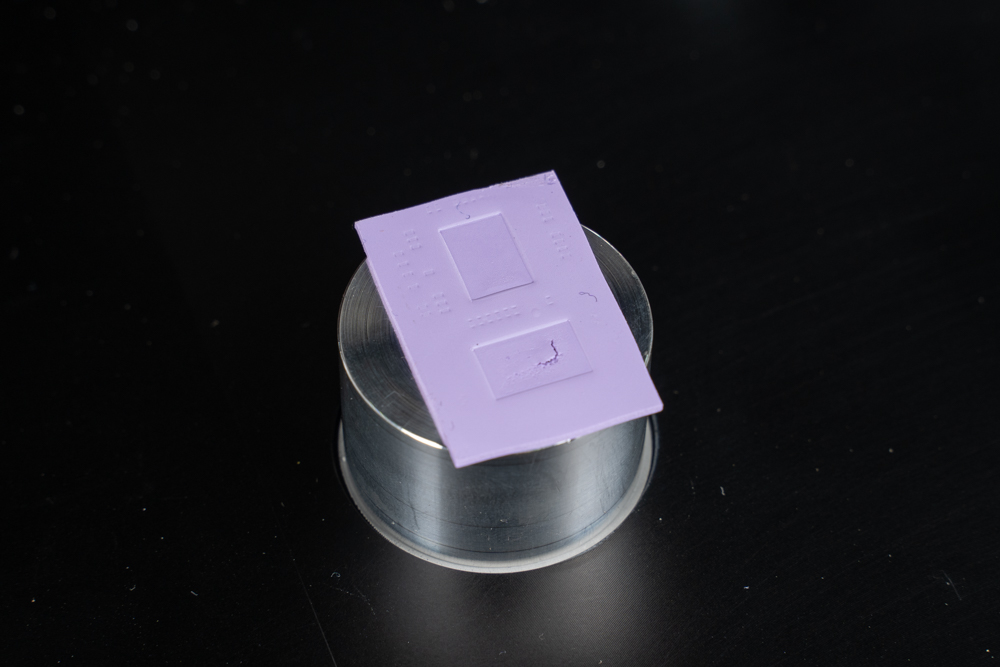

A thermal pad placed on a metallic surface is part of the heat sink assembly. Thermal pads are used to facilitate efficient heat transfer from the CPU or other heat-generating components to the heat sink. They are designed to fill air gaps and microscopic imperfections, ensuring full contact and thus better thermal conductivity. The pad’s purple color is a common indicator of its composition, and it often includes a silicone base filled with a thermally conductive material. Such thermal pads are a crucial component in fanless systems like the industrial computers we’ve been discussing, as they rely solely on passive cooling mechanisms to manage heat dissipation.

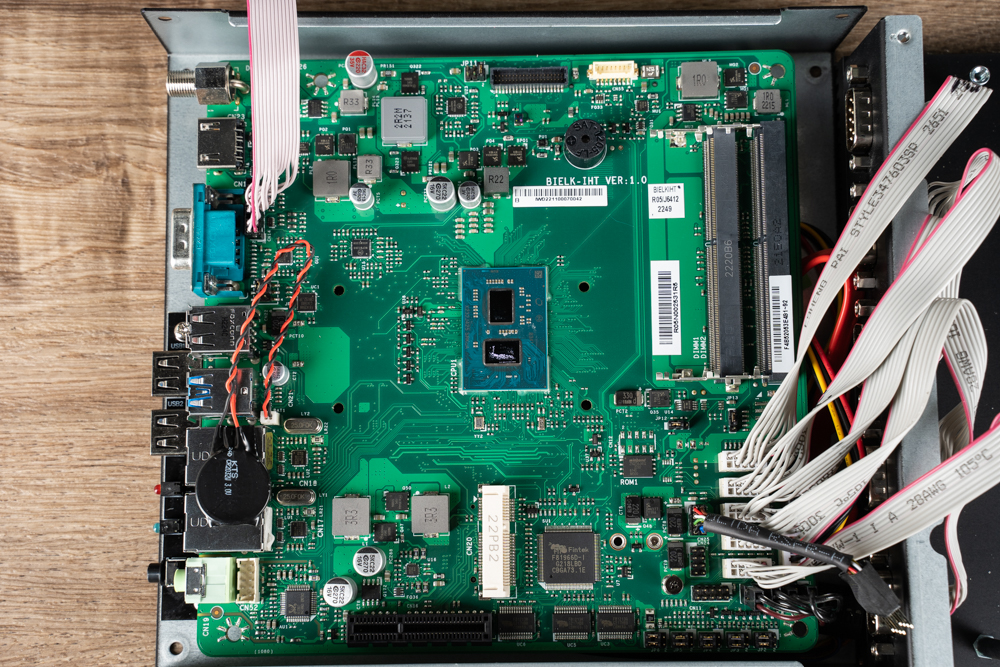

The top view of a motherboard is from the industrial computer system we’ve been examining. Visible components include:

- Memory Slots: There are RAM slots for DDR4 SO-DIMM memory, essential for system operations and performance.

- BIOS Battery: The small, round battery on the board is used to keep the system’s BIOS settings intact when the system is powered off.

- Expansion Slots: These could be for additional connectivity or function expansion, such as M.2 slots.

- Wiring Connectors: Ribbon cables and wire harnesses are connected to various points on the motherboard, which could be used to connect front I/O panels, power buttons, LEDs, or other system components.

- Capacitors and Resistors: These components are part of the electrical circuitry, ensuring proper power regulation and distribution within the system.

- Chipsets: Various integrated circuits, including the system’s CPU, are present and responsible for a range of functions from controlling I/O to managing data transfer between memory and the CPU.

The layout appears to be well-organized, which is typical of industrial-grade hardware designed for reliability and ease of maintenance. It’s clear from this view that the system is built to handle specific tasks that would be typical in an industrial setting, such as machine control, data processing, and connectivity.

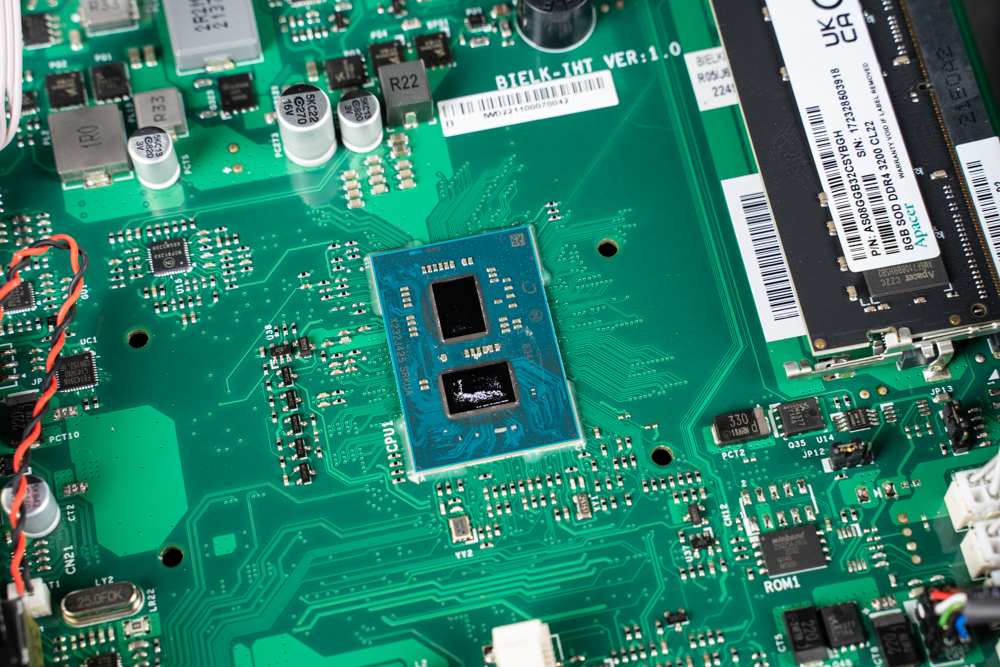

A close-up of the motherboard, centering on the central processing unit (CPU) of the system. This CPU is mounted directly onto the board and typically utilizes a ball grid array (BGA) for permanent installation. There’s no traditional socket here; the CPU is soldered to the motherboard, which is common in compact and industrial computers where space is at a premium and the unit must withstand various stresses without the risk of a socketed CPU becoming dislodged.

Around the CPU, you can observe various other components, like capacitors, that help regulate and supply power to the CPU. The robust design and permanent attachment method of the CPU ensure reliability for the industrial computer during long-term deployment in potentially challenging environmental conditions.

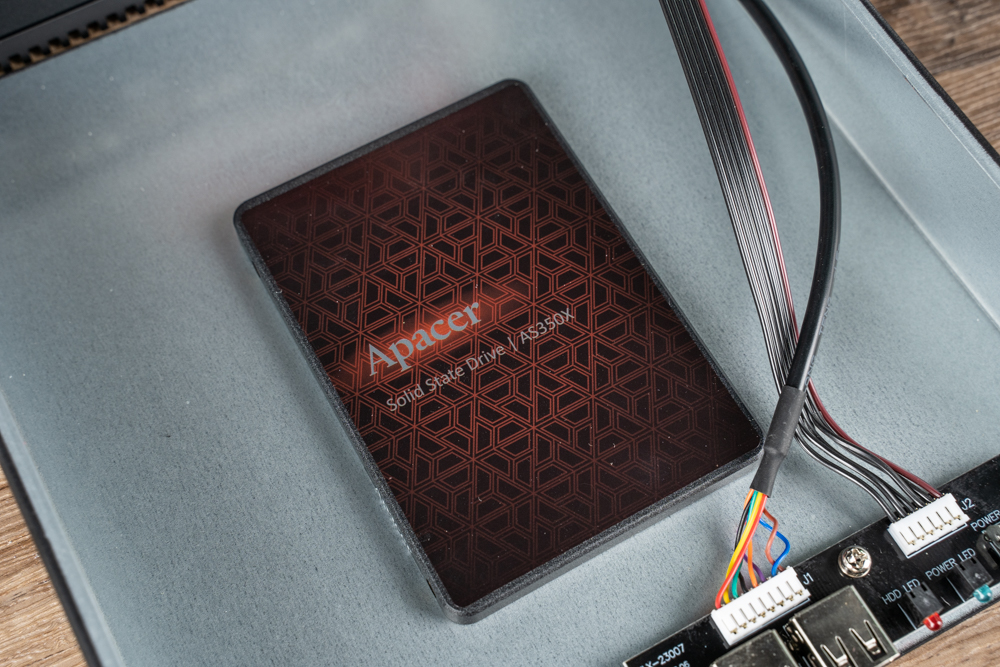

A close-up of an Apacer AS350 solid-state drive (SSD) with a capacity of 256GB. It’s a 2.5-inch SATA SSD, which is a common form factor and interface used in both consumer and industrial computers for storage. SSDs like this are preferred in industrial applications due to their reliability, speed, and resistance to physical shock compared to traditional hard disk drives. The AS350 series from Apacer is designed to provide a balanced performance for everyday computing and industrial use.

An Apacer 8GB SO-DIMM DDR4 3200MHz memory module, a type of RAM commonly used in laptops and compact computers due to its small size. The DDR4 designation refers to the fourth generation of double data rate (DDR) memory, which is faster and more power-efficient than its predecessor, DDR3. A 3200MHz frequency is a high rate of data transfer, indicating that this RAM can provide the system with fast and efficient memory performance, which is particularly important for the multitasking and processing demands of industrial applications. The presence of the CE marking indicates that it meets the European Union’s safety, health, and environmental requirements.

An industrial computer motherboard equipped with two SO-DIMM memory slots, which accommodate DDR4 RAM modules. As indicated by the labeling on the board, this system can support up to a maximum of 32GB of RAM, which is the upper limit of memory supported by the installed processor. This capacity is ample for most industrial and many commercial applications, allowing for efficient multitasking and handling of memory-intensive processes. As seen in the previous image, the installed RAM module from Apacer is one of these two slots, contributing to the system’s overall performance capabilities.

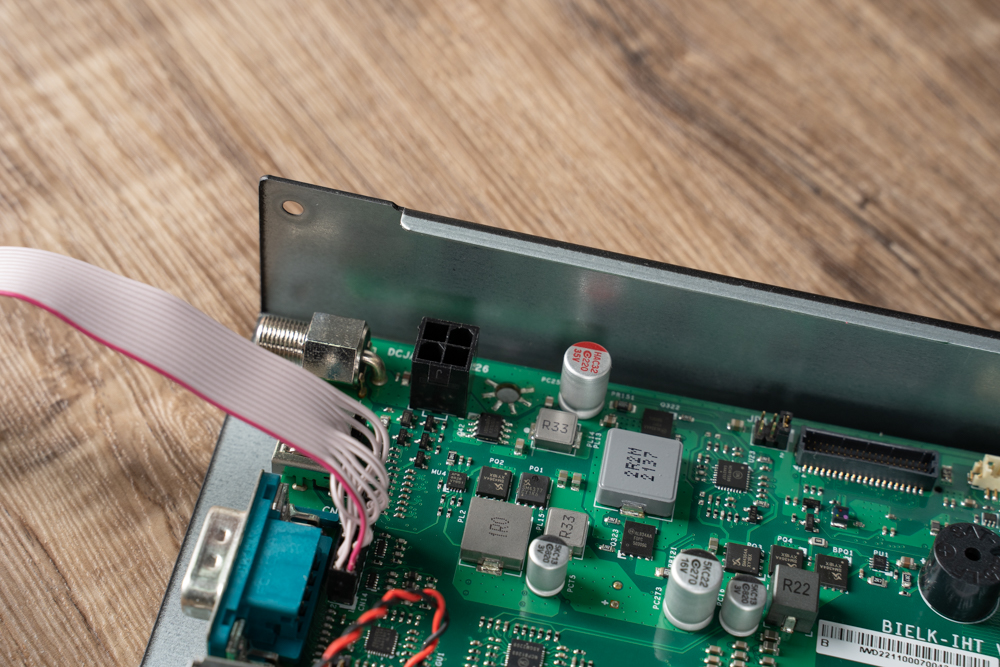

A 4-pin CPU power connector on the motherboard that isn’t being utilized. This connector is typically used to provide additional power to the CPU, especially for those with higher performance demands that may require more power than what the standard motherboard power supply can deliver.

The unused state of the 4-pin connector suggests that the CPU installed in this system doesn’t require additional power, which is often the case with lower-power CPUs like those used in many industrial and embedded systems. This can also imply that the motherboard design is standardized for use in different models, some of which might host higher-power CPUs requiring this additional power connector. By using a standard motherboard across different models, the manufacturer can reduce production costs and streamline the design process.

A close-up of a Mini PCIe (Peripheral Component Interconnect Express) slot on the motherboard. Mini PCIe slots are typically used for adding expansion cards to a computer system, and as noted, one of the common uses for such slots is to install wireless network cards, which can provide Wi-Fi or Bluetooth functionality to the system.

In the context of an industrial computer, the versatility afforded by the Mini PCIe slot is valuable for customization to specific application needs, such as adding cellular modems, solid-state storage, or other specialized interface cards. This enables the system to be tailored to a wide range of industrial tasks that may require different forms of connectivity or data transfer capabilities.

Testing the MT PRO-J6412: Unveiling Performance with Built-In 8GB RAM and 256GB SSD on a 1080P Display

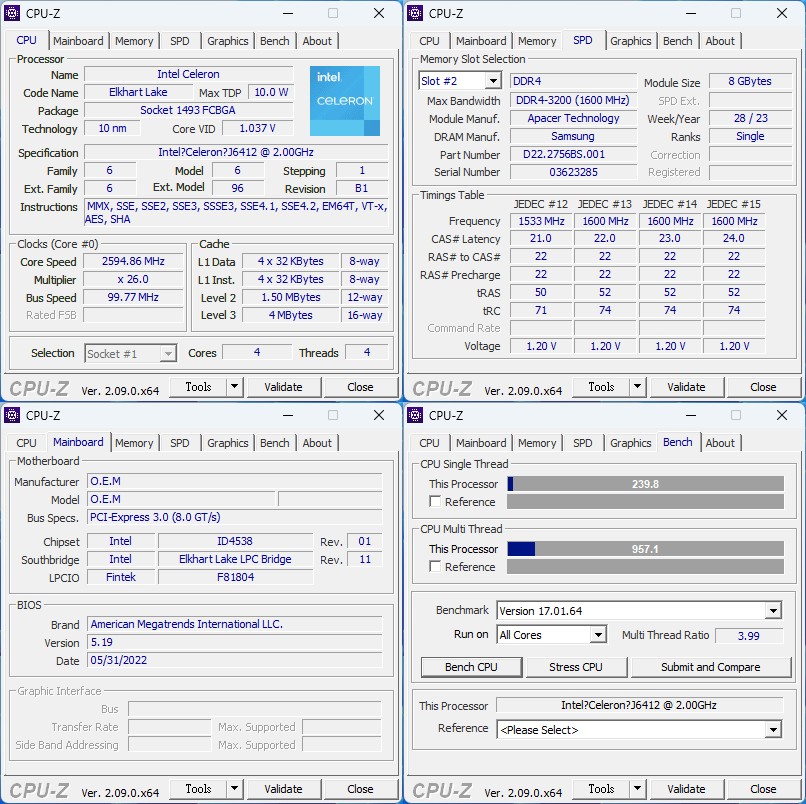

The image displays screenshots of the CPU-Z application, which provides detailed information about the computer’s hardware, particularly the CPU, memory, and motherboard. From these snapshots, we learn the following about the MT PRO-J6412 system being tested:

- CPU: The system is powered by an Intel Celeron J6412 processor, which is an energy-efficient chip with a TDP (Thermal Design Power) of 10W. The processor has a base clock of 2.00GHz and can boost up to 2.60GHz. Power levels are indicated as PL1 at 10W and PL2 at 20W, which are measures of the processor’s power consumption under different operational conditions.

- Memory: The system includes 8GB of DDR4 RAM, which is a significant amount of memory for a range of industrial applications, allowing for robust multitasking and processing capabilities.

- Storage: There’s a 256GB SSD installed, providing fast storage for the operating system, applications, and data.

- Cooling Design: The system uses a passive cooling design, relying on heat sinks rather than fans for heat dissipation, which is ideal for reliability and operation in environments where noise reduction or dust minimization is crucial.

- Display: Tests were conducted using a 1080P display, which indicates the system can handle standard high-definition resolution, suitable for a variety of tasks from monitoring to media playback.

The information from CPU-Z is useful for understanding the performance and capabilities of the system, which appears to be well-suited for applications where low power consumption, reliability, and silent operation are valued.

The image displays the CINEBENCH R20 benchmarking software developed by MAXON, based on their Cinema 4D engine, which is used to evaluate a processor’s performance in 3D content creation tasks, particularly in rendering.

The MT PRO-J6412’s scores are presented:

- CPU (Single Core): 130 pts

- CPU (Multi Core): 636 pts

These scores measure the performance of the Intel Celeron J6412 processor within the system, with a focus on tasks that would be similar to those encountered in 3D modeling and rendering workloads. The single-core score reflects how well the processor performs on tasks that can only utilize one CPU core, while the multi-core score indicates the overall performance when all CPU cores are used.

While these scores may not be high compared to high-end CPUs, especially those designed for intensive 3D rendering tasks, they are respectable for an energy-efficient, low-power processor like the Celeron J6412. It demonstrates that the MT PRO-J6412 can handle basic 3D tasks, which could be sufficient for light industrial and commercial applications that don’t require high-end graphics processing capabilities.

The results of the MT PRO-J6412 running the PCMARK 10 benchmark test. PCMARK 10 is designed to test a system’s performance across tasks typically found in an office environment, such as app start-up, web browsing, video conferencing, and the use of productivity software like spreadsheets and writing tools. It also evaluates performance in digital content creation tasks like photo and video editing.

The MT PRO-J6412 scored a total of 1986 points in this benchmark. The breakdown of the score is as follows:

- Essentials: 5554, measuring basic tasks such as web browsing and video conferencing.

- Productivity: 2312, assessing performance in activities like spreadsheets and writing.

- Digital Content Creation: 1658, gauging the system’s capability in more demanding tasks such as photo and video editing.

These scores reflect the machine’s suitability for office-related workloads and its ability to handle everyday productivity tasks reasonably well. The relatively modest score in digital content creation indicates that while the system can perform such tasks, it might not be the best fit for intensive creative work that requires high computational power. This overall score is quite typical for a system with a low-power CPU like the Intel Celeron J6412, which is designed for efficiency rather than high performance.

The screenshot shows results from a CrossMark benchmark test. CrossMark, developed by BAPCo, is a cross-platform benchmarking tool that assesses a device’s performance across productivity, creative content work, and responsiveness. The test suite includes various tasks such as document editing, spreadsheet manipulation, web browsing, photo editing and organization, video editing, and application and file opening speeds.

The MT PRO-J6412 scored:

- Total: 464 points

- Productivity: 526 points

- Creativity: 402 points

- Responsiveness: 491 points

These scores indicate that the MT PRO-J6412 performs reasonably well in general productivity tasks and has a good responsiveness rating. The creativity score, while lower, still shows capability in tasks that require a moderate degree of processing, such as photo editing and video work. Given the system’s specifications and intended industrial use, these results demonstrate its adequacy for a variety of tasks, though it may not be optimized for highly demanding creative workloads.

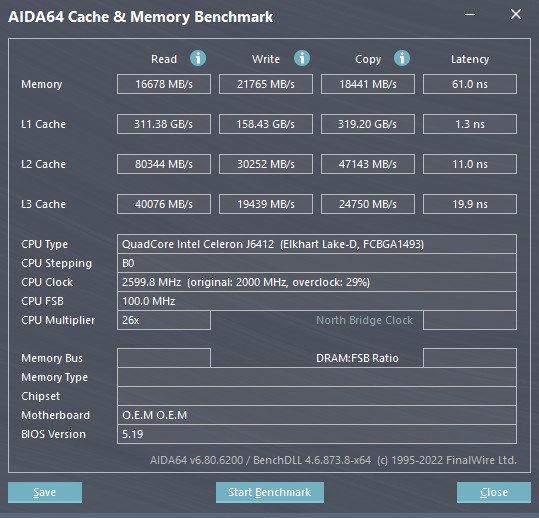

The screenshot displays results from the AIDA64 Cache & Memory Benchmark, a tool used to measure the performance of the system’s memory and cache.

The results for the MT PRO-J6412 are as follows:

- Memory Read: 16678 MB/s

- Memory Write: 21765 MB/s

- Memory Copy: 18441 MB/s

- Memory Latency: 61.0 nanoseconds

These numbers indicate the speed at which the system’s memory performs essential operations: reading, writing, and copying data. The read, write, and copy speeds are quite fast, suggesting that the system is capable of handling memory-intensive tasks efficiently. The latency figure is a measure of how long it takes for a data request to be completed after it’s been made; a lower number is better, and while 61.0 ns is relatively higher than high-performance gaming or workstation computers, it’s still within a respectable range for industrial and general computing tasks.

The overall results indicate that the MT PRO-J6412 has a robust memory subsystem that should support its intended use in industrial applications well.

A window of CrystalDiskInfo, a utility tool for monitoring the health status and providing detailed information about the solid-state drive (SSD) in a system.

Here’s what we can glean from the screenshot:

- The SSD is an Apacer AS350 with a capacity of 256GB.

- The interface is SATA/600, which means the SSD has a potential transfer rate of up to 600 MB/s.

- The tool displays various S.M.A.R.T (Self-Monitoring, Analysis, and Reporting Technology) attributes which are indicators of the drive’s reliability and operational status. All the values are showing “Good”, which means the SSD should be in a healthy condition.

- The SSD’s temperature is currently at 40°C, which is a normal operational temperature for most SSDs.

- The displayed SSD has a used space of approximately 81 GB out of the total 256 GB available, indicating that there’s plenty of storage left for additional data.

This kind of monitoring is important as it can alert users to potential drive failures before they occur, allowing for data backup and drive replacement in a timely manner, thereby preventing data loss. The Apacer AS350 is to provide reliable storage performance for the industrial computer system in which it is installed.

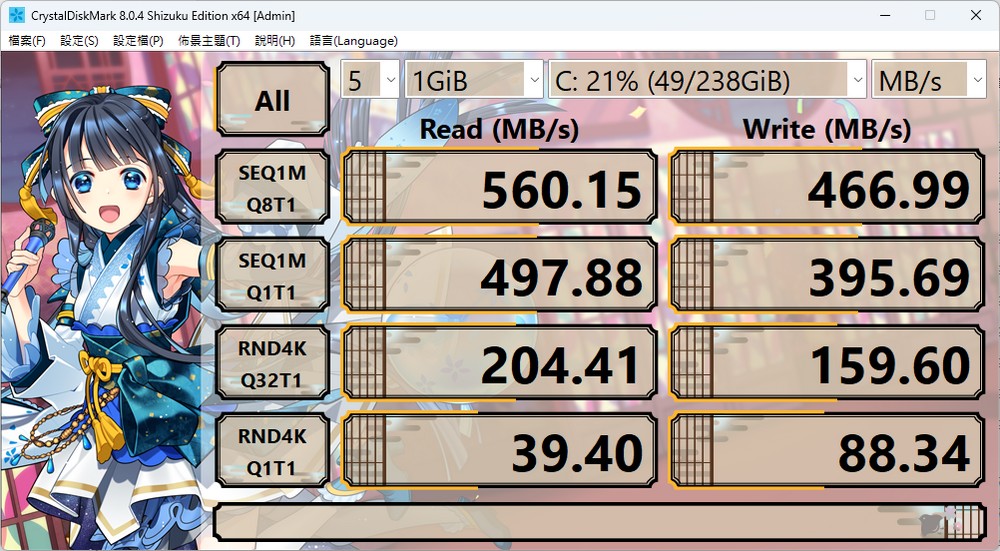

The screenshot is of CrystalDiskMark, a benchmark tool that measures the performance of storage devices like HDDs and SSDs. The test was conducted on an Apacer AS350 256GB 2.5-inch SATA SSD.

The results show:

- Sequential Read Q8T1: 560.15 MB/s

- Sequential Write Q8T1: 466.99 MB/s

- Sequential Read Q1T1: 497.88 MB/s

- Sequential Write Q1T1: 395.69 MB/s

- Random 4K Read Q32T1: 204.41 MB/s

- Random 4K Write Q32T1: 159.60 MB/s

- Random 4K Read Q1T1: 39.40 MB/s

- Random 4K Write Q1T1: 88.34 MB/s

The sequential read and write speeds are close to the upper-performance limits of SATA III SSDs, which max out at around 600 MB/s due to the SATA interface’s bandwidth limitations. The results are indicative of the SSD’s ability to handle typical data transfer tasks efficiently. High sequential speeds are beneficial for tasks that involve transferring large files, while the 4K random read and write speeds are important for understanding how the drive will perform during everyday usage scenarios where small pieces of data are read from and written to various locations on the drive.

Overall, the Apacer AS350’s performance is in line with what’s expected from a modern SATA SSD, offering solid performance for general use and industrial applications.

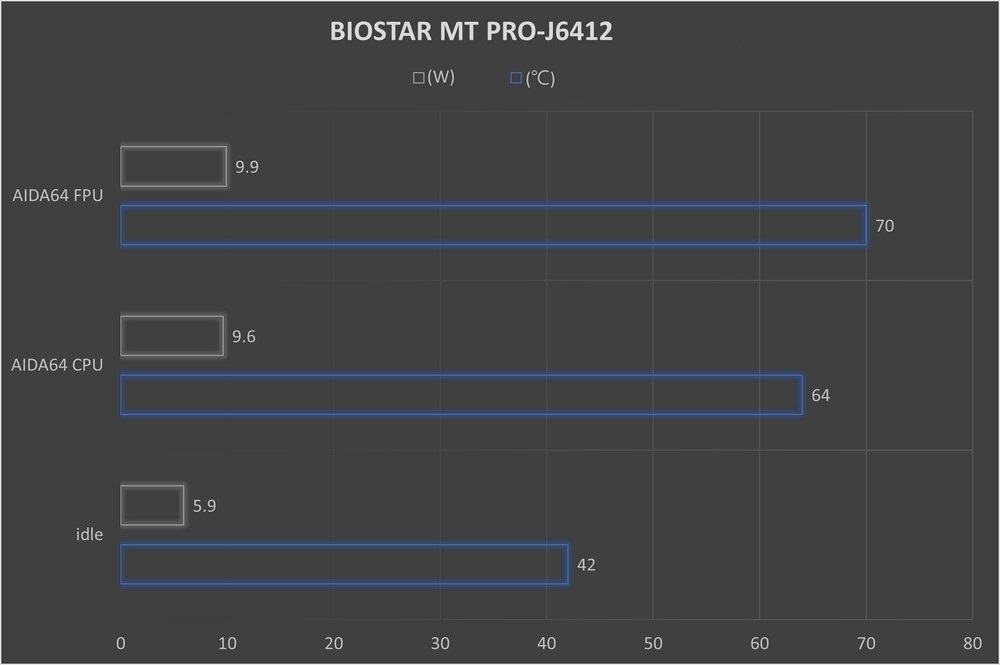

Cooling Efficiency Uncovered: Biostar MT PRO-J6412’s Fanless Passive Design Handles Heat with Ease

The temperature testing results for the BIOSTAR MT PRO-J6412 using a passive, fanless cooling design. The data shows:

- Idle State: At idle, the system maintains a temperature of approximately 42°C, which is a normal and safe operational temperature for most electronic components.

- Under Load: During the AIDA64 CPU and FPU stress tests, the system was able to maintain the power consumption at PL1 (10 watts), with the temperature peaking at 70°C.

The fact that the temperature did not exceed 70°C under load is notable, as it demonstrates the efficiency of the passive cooling system even when the CPU is operating at its boost frequency of 2.6GHz across all four cores. This is impressive, considering that passive cooling does not involve active airflow and relies entirely on heat sinks and the chassis design to dissipate heat.

Maintaining these temperature levels under load is crucial for the reliability and longevity of the system, especially in industrial environments where equipment may be expected to operate continuously over long periods. The performance of the MT PRO-J6412 in these thermal tests suggests that it is well-suited for sustained use in scenarios where active cooling solutions are undesirable or impractical.

Summarize

In summary, the BIOSTAR MS-J6412 and MT PRO-J6412 systems are designed to meet the needs of industrial control, commercial equipment, and Edge AI applications. Despite their fanless passive cooling design, these systems efficiently harness the potential of the J6412 processor, offering a compact form factor rich in I/O options. This makes them highly adaptable for a wide range of uses such as POS systems, cloud node computers, 4G/5G IoT applications, facial recognition, and other diverse setups. Notably, the inclusion of a built-in SIM card slot for 4G/5G mobile network connectivity stands out as a distinctive feature, especially useful in scenarios without wired networks or Wi-Fi.

Regarding the MT PRO-J6412 tested here, with a retail price of around TWD 14,000 on e-commerce platforms, one could potentially find systems with higher performance at this price point. However, when considering the specific combination of passive cooling, compact size, and low power consumption, the options become limited. The choice ultimately comes down to how well the MT PRO-J6412’s extensive expandability fits the user’s requirements. This system offers a balance of performance and flexibility that is well-suited for specialized industrial and commercial environments.

If this article is helpful for you, please share this article with your friends on social media. Thank you!

This article is based on the personality of the reviews. You are responsible for fact-checking if the contents are not facts or accurate.

Title: Maximizing Efficiency in Compact Spaces: A Review of BIOSTAR MS-J6412 and MT PRO-J6412 Industrial Computers