Scythe has recently unveiled its latest CPU air cooler innovation, the MUGEN 6. This new addition to Scythe’s cooling solutions lineup brings a fresh approach with a single-tower design featuring six heat pipes. The MUGEN 6 distinguishes itself with a tower body that’s strategically offset backwards and upwards, significantly reducing hardware interference and ensuring compatibility with a wide range of computer cases. Its compact installation height of just 154 mm allows it to fit into most market-available PC cases with ease.

The MUGEN 6 is equipped with the Wonder Tornado 120 PWM fan, known for its exceptional performance. This fan features a detachable anti-vibration rubber pad on its frame to minimize resonance during operation, thereby reducing noise for a superior installation experience.

Key Specifications of the MUGEN 6:

- Product Name: MUGEN 6

- Model Number: SCMG-6000

- Compatibility: Supports various CPU sockets, including Intel’s LGA 1700, 115X, 1200, 2011, and 2066, as well as AMD’s AM4 and AM5.

- Dimensions (with fan): Width 132 x Depth 106 x Height 154 mm

- Heat Pipes: 6mm x 6

- Weight: 1013g

- Fan Name: Wonder Tornado 120PWM – 2000RPM

- Fan Dimensions: 120 x 120 x 26 mm

- Fan Speed: 350 ± 200 to 2000 ± 10% RPM

- Airflow: 7.68 ~ 60.29 CFM

- Air Pressure: 0.05 ~ 2.54 mmH2O

- Noise Level: 3.00 ~ 26.88 dBA

- Rated Voltage: 12V

- Rated Current: 0.15A

- Connector: 4 Pin PWM

The MUGEN 6 stands out as a meticulously designed CPU cooler that not only aims to provide exceptional cooling performance but also focuses on reducing noise and ensuring wide compatibility with different PC builds. Its innovative design and the inclusion of the Wonder Tornado fan make it a compelling choice for enthusiasts looking to enhance their system’s cooling efficiency without compromising on noise or compatibility.

Scythe MUGEN 6: Unveiling the Silver Standard and Stealth Black Dual-Fan Editions for Enhanced Cooling Performance

Scythe’s MUGEN 6 series enhances its lineup with two distinct versions: a standard edition with a silver tower and a black-coated dual-fan version, catering to diverse user preferences for aesthetics and performance. A notable upgrade from its predecessor, the MUGEN 5, is the addition of a top cover on the cooling tower. This design choice not only conceals the heat pipes but also significantly improves the overall look, making the MUGEN 6 much more visually appealing than the previous generation.

Despite its refined appearance, the MUGEN 6 maintains a compact size of 132 x 106 x 154mm and a weight of 1013g, positioning it as a sleek, high-end single-tower air cooler. It stands out in the market for those who prioritize a minimalist design, as it eschews RGB lighting for a more sophisticated, understated elegance. This focus on simplicity and efficiency without the addition of RGB lighting appeals to users who prefer a clean and professional setup.

The MUGEN 6 series represents a perfect blend of style, functionality, and advanced cooling technology. Whether users opt for the classic elegance of the silver standard version or the sleek sophistication of the black-coated dual-fan model, they’re guaranteed a top-tier cooling solution. Scythe’s commitment to combining aesthetic appeal with high performance in the MUGEN 6 series ensures that it meets the needs of a wide range of computer enthusiasts, from those building a high-performance gaming rig to professionals seeking a quiet and efficient workstation.

The product packaging for the Scythe MUGEN 6 CPU Cooler, emphasizing its sleek and modern design. The box presents a clean and professional appearance, predominantly white with green accents, reflective of the Scythe brand’s color scheme. A high-resolution image of the MUGEN 6 cooler is prominently displayed, showcasing the product’s sophisticated black cooling fins and the distinctive Wonder Tornado 120 PWM fan.

This packaging design conveys important information at a glance, ensuring that potential buyers can easily recognize the product’s purpose and its compatibility with their CPU setup. The use of clear, bold typography to label the product reinforces its identity and aids in brand recall. The overall presentation is straightforward, emphasizing functionality and quality, aligning with the product’s positioning as a high-end, performance-oriented CPU cooling solution.

The back of the Scythe MUGEN 6 CPU Cooler’s box displays a concise and informative specification table, providing a quick overview of the product’s key features and capabilities. The table is designed to be easily readable, with a clean layout that aids consumers in understanding the product they are considering.

Highlighted features on the box include:

- Compatibility with Intel LGA 1700 and AMD AM5 sockets, indicating its readiness for current generation CPUs.

- The height of the cooler at 154 mm (or 6.06 inches), ensuring it fits in a variety of PC cases.

- The presence of a PWM fan with dimensions of 120 x 120 x 26 mm, showcases the cooler’s efficient airflow design.

- Six 6 mm heat pipes, pointing to its robust heat dissipation capabilities.

- An asymmetrical design, which suggests thoughtful engineering for improved compatibility and performance.

The box also lists detailed specifications like the weight (1013g, including the fan), fan speed (350 to 2000 ± 10% RPM), noise level (3.00 – 26.88 dBA), airflow (7.68 – 60.29 CFM), static pressure (0.05 – 2.54 mmH2O), and bearing type, among other things. There’s also a note regarding the fan speed control, which is managed by the PWM signal from the motherboard, allowing for dynamic speed adjustment based on system performance needs.

The contents of the Scythe MUGEN 6 CPU Cooler as it appears upon unboxing. The main components visible are:

- The heat sink tower, which features a dense array of black cooling fins. This is the primary component responsible for dissipating heat away from the CPU.

- The Wonder Tornado fan, which is designed to attach to the heat sink, providing the airflow necessary for cooling. Its black color matches the heat sink, maintaining a consistent and sleek aesthetic.

- A small cardboard box that likely contains the mounting hardware and accessories, essential for securing the cooler to the motherboard and ensuring compatibility with various CPU sockets.

The packaging is practical and appears to be designed with safe transit in mind, with foam padding to protect the components from damage during shipping. The layout is organized, making the installation process straightforward for the user by keeping the parts accessible and ready for assembly. This presentation not only protects the product but also conveys a sense of quality and attention to detail that users would appreciate.

The complete set of components provided with the Scythe MUGEN 6 CPU Cooler. The items laid out for view include:

- The heat sink tower itself, which boasts a series of metal fins and heat pipes designed to efficiently dissipate heat from the CPU.

- The Wonder Tornado fan, characterized by its distinctive black blades, which is meant to be attached to the heat sink to facilitate active cooling through airflow.

- A package containing various mounting brackets, screws, and parts, which are the essential fittings for installing the cooler onto the motherboard and ensuring stable attachment to various CPU socket types.

- A screwdriver, which is a thoughtful inclusion, enabling the user to assemble the components without needing additional tools.

- The instruction manual, which is crucial for guiding users through the installation process. It includes a QR code, presumably to offer the user access to an online manual or installation video for additional help.

The presentation is neat and orderly, reflecting a user-friendly approach to product setup. By including the necessary tools and clear instructions, Scythe ensures that even those who may be less experienced with hardware installations can confidently set up their new CPU cooler. This comprehensive package underlines the company’s commitment to customer satisfaction and product accessibility.

A detailed view of the Scythe MUGEN 6 CPU Cooler’s mounting hardware, which is designed to support both Intel and AMD platforms. The components shown include:

- A backplate with pre-installed standoffs. This is the foundational piece that mounts directly to the motherboard’s underside, providing a secure anchor for the cooler.

- Mounting brackets that will be attached to the base of the heat sink. There are typically two sets for compatibility: one pair for Intel sockets and another for AMD sockets.

- Screws and spacers are necessary to secure the brackets to the motherboard and maintain the correct height for the cooler.

- Thumbscrews or similar fasteners that are used to firmly attach the heat sink to the mounting brackets, ensuring that it stays in place over the CPU.

These components are crucial for a secure and compatible installation across different motherboard layouts and CPU socket types. The inclusion of specialized hardware for both major CPU manufacturers highlights the cooler’s versatile design, catering to a broad range of users and setups. The precision engineering of these parts is essential for optimal cooler performance, ensuring proper contact with the CPU for efficient heat transfer.

The image presents a tube of Scythe-branded thermal paste alongside a plastic spatula, which is an applicator tool. Thermal paste, also known as thermal compound or thermal grease, is a thermally conductive chemical compound that is a crucial component in the CPU cooling process. It is applied between the CPU and the heat sink to enhance the thermal conductivity of the interface, allowing for more efficient heat transfer from the CPU to the heat sink. The inclusion of the thermal paste and spatula in the Scythe MUGEN 6 CPU Cooler package indicates that Scythe ensures customers have all necessary accessories for installation, right out of the box. This facilitates a complete and efficient setup process, allowing for optimal cooling performance of the CPU once installed. The applicator spatula assists users in applying a smooth, even layer of thermal paste, which is important for achieving the best possible thermal connection between the CPU and cooler.

A set of four metal fan clips, which are designed for attaching a fan to the CPU cooler’s heat sink. These clips are typically used to secure the fan to the heat sink without the need for tools, allowing for a quick and easy installation or removal process.

The fact that there are four clips suggests that they enable the option to mount an additional fan to the Scythe MUGEN 6 CPU Cooler. This can be particularly beneficial for users looking to implement a push-pull configuration, which involves one fan pushing air through the heat sink while another pulls air out the other side, enhancing the cooler’s overall airflow and thermal performance.

Including these extra fan clips is a thoughtful touch from Scythe, as it provides users with the flexibility to upgrade their cooling system in the future, allowing them to customize their setup according to their specific cooling requirements or noise preferences.

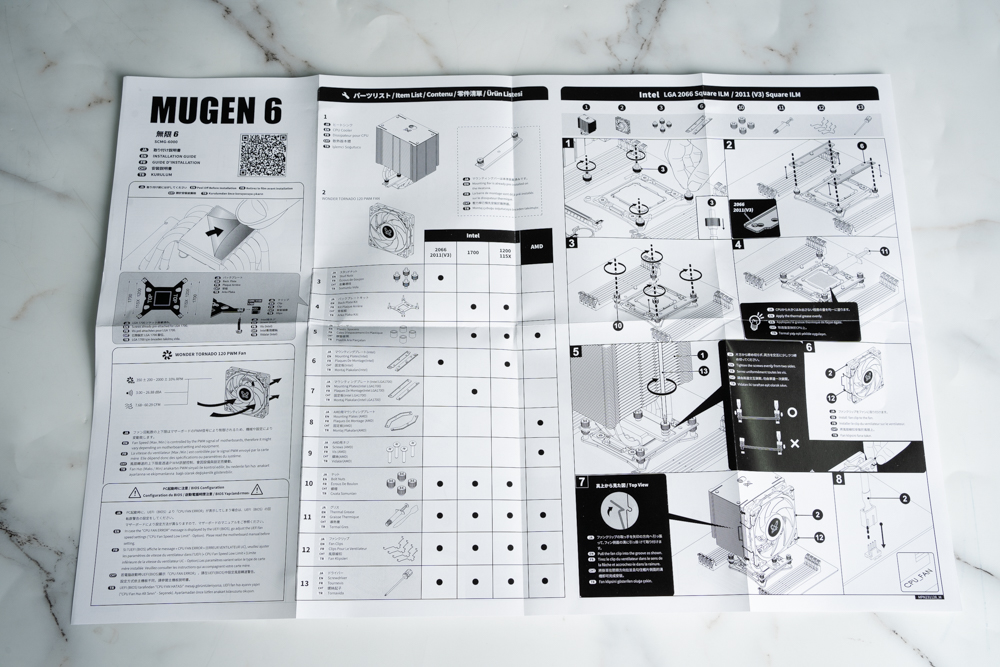

The instruction manual for the Scythe MUGEN 6 CPU cooler, spread open to reveal detailed graphical illustrations and textual explanations for installing the cooler on various CPU socket platforms. The manual is comprehensive and well-organized, providing step-by-step instructions to accommodate different hardware configurations.

The Scythe MUGEN 6 is a meticulously crafted CPU cooler featuring a height of 154mm and a single-tower design. Its internal structure boasts six 6mm diameter heat pipes that weave through the cooling fins, enhancing thermal conductivity and heat dissipation efficiency. The asymmetrical tower design of the MUGEN 6 is a strategic choice, allowing for intuitive avoidance of interference with memory slots on the motherboard during installation. This offset also takes into account the clearance for the motherboard’s Voltage Regulator Module (VRM) cooling components, which is essential for preventing conflicts in hardware setups.

This design demonstrates Scythe’s attention to the user experience, ensuring that the MUGEN 6 not only provides top-tier cooling performance but also considers the ease of assembly and compatibility with other PC components. Such a design is especially beneficial for enthusiasts and gamers who often seek high-performance parts that will not compromise the integrity of their intricate builds. By reducing the potential for hardware interference, Scythe enhances the appeal of the MUGEN 6 to a wide audience, from those building new PCs to those upgrading existing systems.

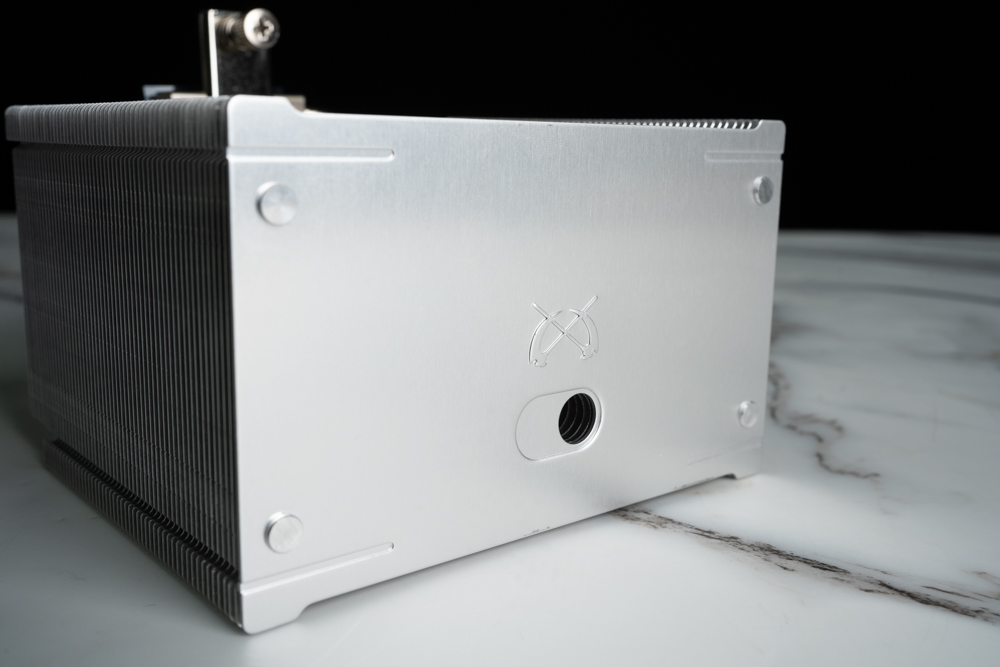

The standard edition of the Scythe MUGEN 6 CPU cooler, with its striking silver tower body. The dense array of finely arranged cooling fins is visible, and engineered to maximize air contact surface area, thus optimizing heat dissipation. The photo also displays the heat pipes curving at the base of the cooler, a design that ensures they efficiently transport heat away from the CPU to the fins.

This silver color scheme of the standard edition provides a classic and clean look, which can blend well with various PC build aesthetics, especially for those who prefer a more traditional or professional appearance over the more common black or RGB-laden coolers.

The craftsmanship of the MUGEN 6 is evident in the precision of the fin alignment and the polish of the metal, emphasizing Scythe’s commitment to quality in both performance and design. This cooler appears to be a solid choice for users who value functionality with a sleek and simple style.

The Scythe MUGEN 6 CPU cooler’s asymmetrical tower design. This architectural choice is crucial, as it allows for ample clearance around the motherboard’s memory modules and VRM heatsinks, effectively minimizing potential installation conflicts. The cooler’s heat pipes are prominently featured as they emerge from the base and curve through the array of aluminum fins, which are engineered to dissipate heat.

This side view demonstrates how the offset design shifts the bulk of the cooler away from the RAM slots, a thoughtful consideration for users with high-profile memory modules or those looking to populate all available memory slots without interference from the cooling unit.

The design reflects a careful balance between aesthetic, function, and compatibility, ensuring that the MUGEN 6 not only performs efficiently but also fits comfortably within a wide range of PC builds. This approach underscores Scythe’s commitment to creating cooling solutions that cater to the practical needs of diverse computer systems.

A close-up of the top cover of the Scythe MUGEN 6 CPU cooler. The cover is an aesthetic enhancement that conceals the typically exposed ends of the heat pipes, providing a more polished look. It features a cutout hole which is likely designed for easy access to the mounting screw, facilitating the installation or removal of the cooler without having to remove the entire top cover.

Prominently etched on the cover is the Scythe logo, adding a subtle branding touch that complements the cooler’s sleek design. This top cover not only improves the appearance but may also offer a minor protective function, preventing accidental contact with the heat pipes.

The attention to detail in this design element speaks to Scythe’s commitment to combining functionality with a refined visual appeal. It ensures that their product can integrate seamlessly into the overall aesthetics of a user’s PC build while maintaining its practical purpose.

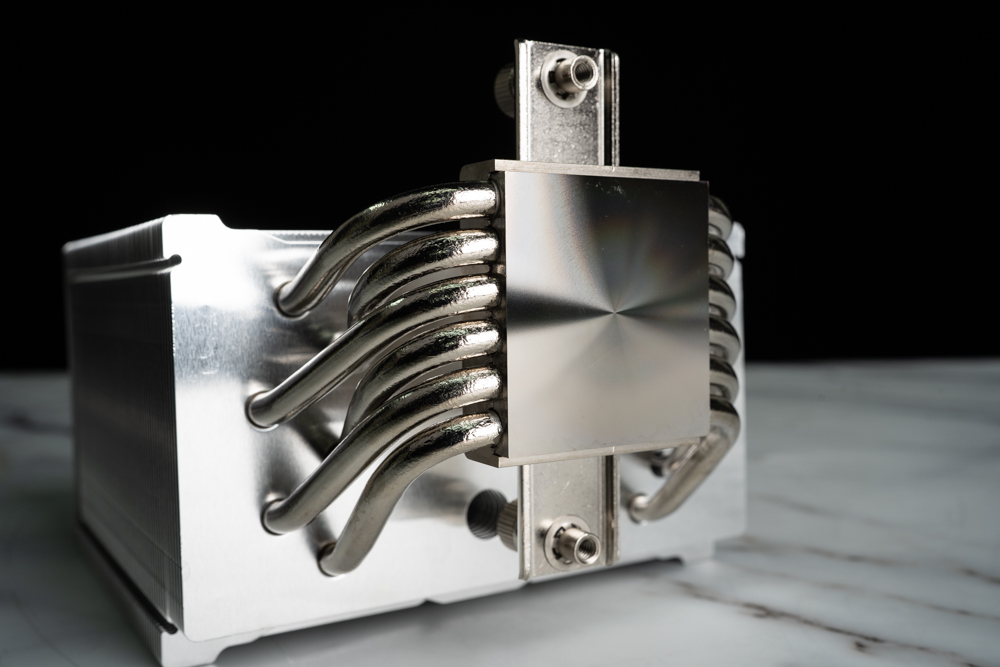

A close-up view of the Scythe MUGEN 6 CPU cooler’s heat pipes and base. The six heat pipes, each with a diameter of 6mm, are prominently displayed, showcasing their polished finish. These heat pipes are engineered to transport heat efficiently from the base to the fin stack, which is critical for effective cooling.

Also featured is the cooler’s base, which appears to have a mirror-like finish, indicative of a smooth copper base. This kind of finish is essential for optimal thermal contact between the CPU and the cooler, as it ensures that the thermal paste can be spread thinly and evenly, eliminating air pockets and enhancing heat transfer.

The meticulous design and construction are evident, with the heat pipes arranged to maximize contact with the base, thus ensuring the rapid conduction of heat away from the CPU. This design detail underlines Scythe’s dedication to high-performance cooling solutions. The aesthetic appeal of the polished heat pipes and mirror-finished base also speaks to the quality and care put into the manufacturing process, aligning with the expectations of consumers looking for both functionality and visual appeal in their hardware components.

The Scythe MUGEN 6 series offers users two distinct models to choose from: the Standard Edition and the Kuro (Black) Twin Fan Edition. While both versions utilize the same 120mm Wonder Tornado fans, known as Kaze Maru in some markets, the primary distinction lies in the aesthetic and the number of fans included.

The Standard Edition features the natural silver color of the aluminum fins and heat pipes, giving it a classic, sleek look that appeals to users who prefer a more traditional aesthetic or want the cooler to blend seamlessly into their system’s design.

On the other hand, the Kuro Twin Fan Edition differentiates itself with an ED (Electro-Deposition) Coating, which provides a black finish to the entire cooler for a more stealthy and aggressive appearance. This version typically comes with two of the Wonder Tornado fans, allowing for a push-pull configuration that can offer improved airflow and cooling performance compared to the single fan setup.

Both editions of the MUGEN 6 feature the Wonder Tornado fan, which is characterized by its nine blades and SPFDB (Sealed Precision FDB), a fluid dynamic bearing system that promises quiet operation and long-term reliability. The inclusion of removable rubber vibration-dampening pads on the fan frame is a thoughtful detail aimed at reducing vibrational noise, which can be a significant factor in the overall noise level of a PC build.

With a wide range of speeds from 350±200 RPM to 2000±10% RPM, and the ability to adjust these speeds via a 4-pin PWM connection, users can fine-tune their cooling performance to strike the perfect balance between noise and temperature, depending on their individual needs or activities, be it gaming, content creation, or daily computing tasks.

In summary, the Scythe MUGEN 6 series offers versatility and performance, with options catering to different aesthetic preferences and cooling requirements, all the while maintaining a focus on low-noise operation and robust build quality.

The Scythe Wonder Tornado 120 PWM fan, also known as the Kaze Maru 2000 PWM, is a component of the MUGEN 6 CPU cooler series. This fan features a black design with nine blades, optimized for high airflow and static pressure performance essential for effective cooling in CPU air coolers.The fan includes PWM (Pulse Width Modulation) functionality, allowing for dynamic speed control from 350 RPM to a maximum of 2000 RPM. This enables the fan to run at lower speeds when the system is cool for quiet operation

and speed up when necessary during high CPU loads to ensure efficient cooling.

The corners of the fan frame have mounting points with rubber pads, which are likely the removable anti-vibration pads mentioned earlier. These pads help to dampen vibrations between the fan and the heat sink or case, reducing noise that can be caused by the fan’s operation.

Prominently displayed in the center of the fan is the Scythe logo, reinforcing the brand’s identity. The fan’s design suggests a balance between performance and noise reduction, suitable for enthusiasts looking for an effective cooling solution that doesn’t compromise on quietness.

A side perspective of the Scythe Wonder Tornado 120 PWM fan. Notably, the fan frame has arrow indicators that show the direction of airflow and the orientation of the fan blades’ rotation. These arrows are an essential guide for users during installation to ensure that the fan is mounted correctly for optimal air movement within the CPU cooler or case.

The arrow pointing outwards from the center of the fan denotes the direction in which air is expelled, signifying that this side should face away from the heat sink if you’re intending to push air through it. Conversely, it should face towards the heat sink for a pull configuration. The rotational arrow indicates which way the blades will spin, which is useful for aligning the fan with the desired airflow path within the system.

Having these indicators is a helpful detail, especially for users who are less experienced with PC building, as incorrect fan orientation can lead to suboptimal cooling performance. It’s these user-friendly design elements that contribute to a smooth installation process and ensure that the cooling solution performs to its full potential.

The 4-pin PWM (Pulse Width Modulation) connector of the Scythe Wonder Tornado 120 PWM fan. The 4-pin design is critical for allowing precise control over the fan’s speed via the motherboard’s PWM signal. This means that the fan speed can be dynamically adjusted based on the CPU’s temperature, ensuring optimal cooling efficiency and minimizing noise levels when full speed is not required.

The cable appears to be sleeved, which is a quality feature that adds durability and aesthetic appeal, keeping the internal look of the computer build neat and tidy. The sleeving also helps protect the wires from damage, which can be important in setups where the cables might come into contact with other components or sharp edges.

The inclusion of a PWM connector is an advantage for users who want to fine-tune their cooling performance or have the system automatically adjust the fan speeds based on the thermal demands of the CPU. This level of control is particularly appreciated by enthusiasts and professionals who need their systems to operate efficiently under varying load conditions.

Scythe MUGEN 6 Cooler Installation Guide: Seamless Setup for Intel and AMD Platforms

The Scythe MUGEN 6 offers broad compatibility, supporting a range of sockets for both Intel and AMD platforms. The inclusion of full metal mounting brackets ensures a secure and durable installation, contributing to the cooler’s overall robust build quality.

For Intel platforms, such as the ASUS Z790 CREATOR WIFI motherboard, the installation process begins with the assembly of the backplate, which is crucial for providing the support needed for the cooler. It’s important to note that the LGA 1700 socket has a different mounting hole pattern compared to other Intel sockets, such as 115X, 1200, 2011, and 2066. This means the MUGEN 6 includes a specific set of brackets or an adjustable backplate that is compatible with the LGA 1700 socket’s unique requirements.

For AMD platforms, like the ASROCK B650E TAICHI motherboard, which supports the new AM5 socket, users will also need to use the corresponding mounting hardware provided by Scythe. The AM5 socket is a continuation of the AM4 socket’s design, but it’s always recommended to follow the MUGEN 6’s installation instructions closely to ensure proper fitting and optimum cooler performance.

When installing on either platform, attention to detail is key. Users should carefully follow the included manual to select the correct parts and follow the steps tailored for their specific CPU socket. Proper installation is essential not only for the cooler to perform at its best but also to avoid any potential damage to the motherboard or CPU due to incorrect mounting pressure or alignment.

The specialized mounting brackets and nuts are designed for the Intel LGA 1700 socket, which is part of the Scythe MUGEN 6 CPU cooler’s mounting hardware. These metal brackets are engineered to align with the LGA 1700 socket’s unique mounting points on the motherboard.

The LGA 1700 socket, used for Intel’s Alder Lake and newer CPU generations, has a different hole pattern compared to previous Intel sockets, necessitating a dedicated set of mounting hardware. This ensures that the cooler can be securely and correctly attached to the motherboard, providing optimal contact pressure for efficient heat dissipation.

The accompanying nuts are likely to be used to secure the brackets to the motherboard from the backside, creating a stable foundation onto which the cooler is mounted. The quality and durability of full metal brackets and fasteners are critical for maintaining the cooler’s position, especially considering the weight and size of high-performance air coolers like the MUGEN 6.

For users upgrading their systems or building new ones with the LGA 1700 socket, this mounting kit will be an essential part of the installation process to ensure that the cooler performs to its fullest potential.

A metal backplate designed specifically for Intel platforms, which is a component of the mounting system for the Scythe MUGEN 6 CPU cooler. This backplate will sit on the reverse side of the motherboard, providing the structural support necessary for the cooler.

The backplate is outfitted with four protruding screws that align with the motherboard’s CPU socket mounting holes. These will pass through the motherboard from the back, allowing the mounting brackets to be attached on the front side around the CPU area. The black spacers fitted around each screw serve to ensure the backplate maintains the correct distance from the motherboard, preventing any potential damage or short circuits.

This metal backplate is a crucial element of the cooler’s secure mounting mechanism, particularly for heavy-duty coolers like the MUGEN 6. Its durable construction ensures that it can adequately support the weight of the cooler, distribute mounting pressure evenly, and contribute to the overall stability of the CPU cooling setup.

The initial step in mounting a CPU cooler onto an Intel motherboard, which in this case, is the ASUS Z790 CREATOR WIFI. It shows the metal backplate already positioned on the back of the motherboard, with the protruding screws passing through the motherboard mounting holes around the CPU socket. On the front side of the motherboard, plastic spacers have been added onto the screws to secure the backplate in place and maintain the necessary distance from the board.

This step is crucial for stabilizing the backplate and ensuring that the cooler will be mounted with even pressure distribution across the CPU, which is important for optimal heat transfer and cooler performance. The use of spacers prevents the metal backplate from making direct contact with the motherboard, which could potentially cause electrical shorts or damage to the board.

Once the backplate is securely fastened with these spacers, the next steps would typically involve attaching the mounting brackets that will hold the cooler in place, applying thermal paste to the CPU, and then securing the cooler onto the prepared mounting hardware. Each step must be performed with care to ensure the cooler is installed correctly for the best possible cooling efficiency and system stability.

In this image, we can see the next step in the installation process for an Intel LGA 1700 compatible CPU cooler on the ASUS Z790 CREATOR WIFI motherboard. The specific mounting brackets that correspond to the LGA 1700 socket have been placed on the posts protruding through the motherboard, and four nuts are being used to secure the brackets in place.

This is a crucial stage where the brackets are tightened to a specified torque to ensure they are secure but not overly tightened, which could damage the motherboard. These brackets will serve as the anchor points for the CPU cooler, allowing it to be mounted securely and aligned properly over the CPU for optimal thermal contact.

The precision with which these components fit together demonstrates the manufacturer’s attention to compatibility and ease of installation, ensuring that users can install their cooling solution without needing to exert excessive force or make modifications. Proper installation is key to maintaining the cooler’s efficiency and the longevity of both the cooler and the motherboard.

A crucial step in the installation of the Scythe MUGEN 6 CPU cooler onto an Intel motherboard. The cooler’s heat sink has been positioned onto the CPU, with the mounting bars in place on either side of the heat sink, ready for the pressure lever or retention mechanism to be secured.

The small hole in the top of the heat sink cover provides access to the screws that will be tightened to secure the pressure lever. An appropriately sized screwdriver is inserted through this hole to reach the screws, which are typically tightened in an alternating pattern to ensure even pressure distribution across the CPU IHS (Integrated Heat Spreader). This method helps prevent warping or damage to the CPU and ensures optimal contact between the CPU and the heat sink for efficient heat transfer.

The positioning of this access hole is a thoughtful design aspect, enabling the user to secure the cooler without needing to remove the decorative top cover, which maintains the aesthetic appeal of the cooler while also ensuring practical functionality during the assembly process.

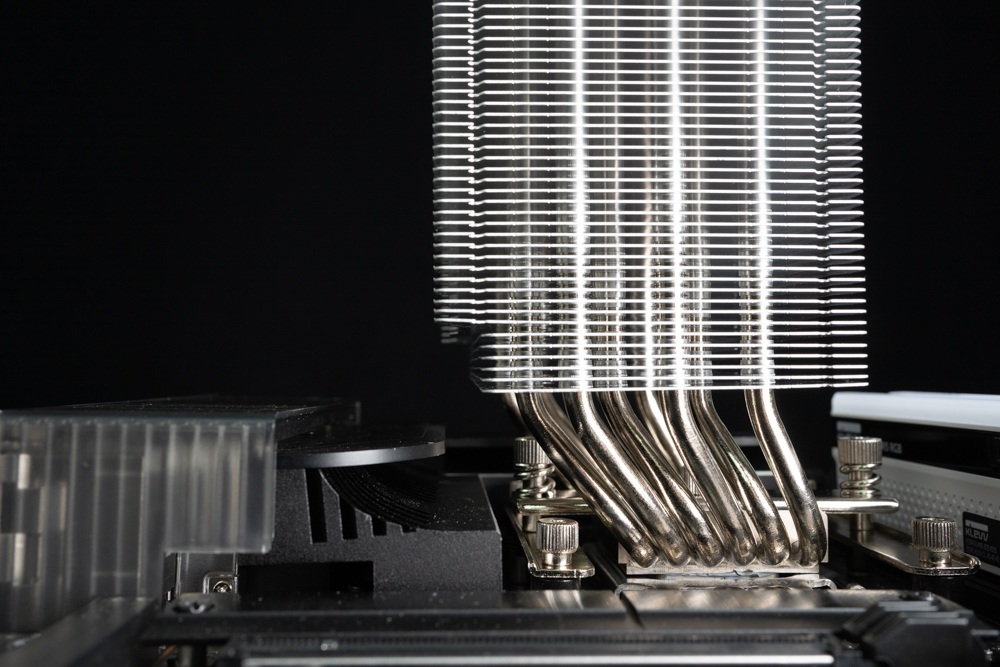

The installed Scythe MUGEN 6 CPU cooler on a motherboard, illustrates how the design of the heat sink accommodates space for the motherboard’s surrounding components. The cooler’s heat pipes are bent in a way that allows the main body of the heat sink to be offset from the base, providing clearance for the motherboard’s VRM (Voltage Regulator Module) heatsinks and other components.

This clearance is vital as it prevents any physical interference between the large CPU cooler and the often-substantial VRM heatsinks found on performance-oriented motherboards, like the one pictured here. This thoughtful design ensures compatibility with a wide range of motherboards, allowing for better airflow and ease of access to nearby components, such as RAM slots, which might need to be upgraded or replaced in the future.

Such a feature is particularly beneficial for users who might have motherboards with larger VRM heatsinks or who utilize memory modules with tall heat spreaders. It shows that Scythe has considered various build scenarios to ensure that the MUGEN 6 can be used in diverse system configurations without issue.

The final step of the Scythe MUGEN 6 CPU cooler installation, where the fan is being secured to the heat sink using the wire clips. These clips hook onto the sides of the fan and are then pulled back to latch onto specific notches or grooves in the heat sink’s sides, ensuring the fan is firmly attached to the heat sink.

This type of fan mounting mechanism is convenient as it allows for easy installation and removal of the fan, facilitating maintenance such as cleaning or replacing the fan if necessary. It also minimizes the use of tools and makes the process user-friendly.

The positioning of the fan is crucial as it directs airflow through the heat sink’s fins to optimize the cooler’s performance. It’s important to ensure the fan is mounted so that it blows air through the heat sink and out the back or top of the case, depending on the case’s airflow configuration.

The assembled configuration demonstrates the careful consideration of compatibility and space efficiency, ensuring that the fan and heat sink do not interfere with the RAM slots or other motherboard components, providing a high-performance cooling solution that fits seamlessly within the system build.

The Scythe MUGEN 6 CPU cooler is fully installed on a motherboard, with the fan mounted and a slight gap maintained between the cooler and the RAM modules. This gap ensures there is no physical contact between the cooler and the memory, preventing any potential issues related to overheating or installation conflicts.

The cooler’s design, which strategically offsets the heat sink to avoid interfering with the RAM slots, is evident here. This thoughtful engineering is particularly advantageous for users who have high-profile RAM sticks with tall heat spreaders, as it allows for unobstructed airflow and easy access to the memory modules should they need to be upgraded or replaced.

The completed assembly showcases a well-integrated cooling solution that balances performance with compatibility, ensuring that the cooler does not encroach upon adjacent components while still providing effective heat dissipation for the CPU. It’s clear that Scythe has designed the MUGEN 6 with consideration for the diverse configurations found in modern PC builds.

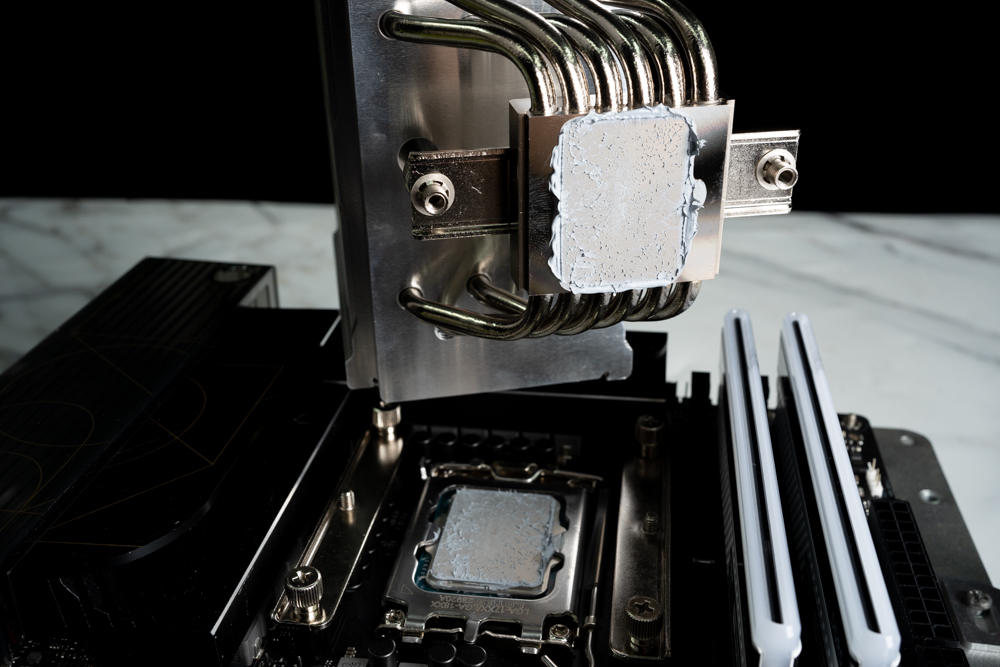

The bottom of the Scythe MUGEN 6 CPU cooler’s heat sink where the thermal paste has been applied. The paste appears to be spread evenly across the surface which will make contact with the CPU, which is essential for efficient thermal conductivity. Even the

application of thermal paste is crucial as it fills in any microscopic imperfections on the surfaces of both the CPU and the heat sink, ensuring maximum heat transfer. The amount of thermal paste used here is appropriate — not too much to cause overflow when the cooler is mounted, and not too little to leave gaps.

This step in the cooler installation process is one of the most critical. An even, thin layer of thermal paste helps to eliminate air pockets that can act as insulators and reduce the cooler’s effectiveness. Proper application can significantly affect the CPU’s operating temperatures and overall system performance.

The mounting brackets and hardware for the AMD platform, part of the Scythe MUGEN 6 CPU cooler’s installation kit. For AMD motherboards, like those with AM4 or the new AM5 sockets, the installation utilizes the motherboard’s original backplate, which simplifies the mounting process.

The components include:

- Two metal mounting brackets designed to fit AMD’s mounting points.

- Four thumbscrews for securing the brackets to the motherboard’s backplate.

- Four plastic spacers that go over the motherboard standoffs, which serve to protect the motherboard from direct contact with the metal brackets and ensure the correct height for the cooler.

For AMD installations, these spacers are placed over the protruding standoffs of the motherboard’s backplate, and the metal brackets are positioned on top. The thumbscrews are then used to secure the brackets in place, providing a stable foundation for the cooler to be mounted.

This mounting method is generally more straightforward compared to some Intel installations because it leverages the existing backplate, reducing the number of steps required to install the cooler. This ease of installation is a beneficial feature for builders of all skill levels, ensuring a hassle-free setup and a secure fit for the CPU cooler.

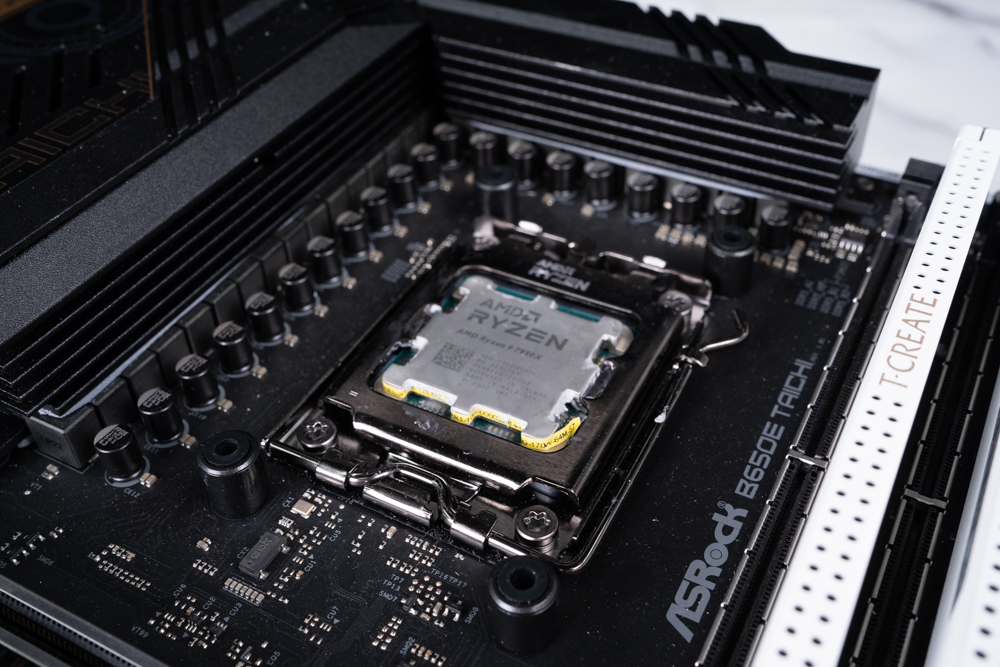

A stage in the process of installing a CPU cooler onto an AMD motherboard – specifically, an ASRock B650E TAICHI motherboard with a Ryzen CPU installed. Shown are the four plastic spacers placed over the motherboard’s existing backplate standoffs, preparing for the installation of the cooler’s mounting brackets.

These plastic spacers are critical as they provide insulation from electrical components and ensure that the metal brackets do not come into direct contact with the motherboard, which could cause damage or a short circuit. They also help to maintain the correct standoff height for the cooler to be mounted, which is important for proper alignment and pressure distribution on the CPU.

Once the spacers are in place, the next step would involve placing the metal mounting brackets over the spacers and securing them with screws or thumbscrews, depending on the cooler’s design. This will create the mounting points to which the CPU cooler will be attached. The use of such a setup is common in aftermarket cooling solutions for AMD platforms, as it leverages the motherboard’s built-in backplate, simplifying the installation process.

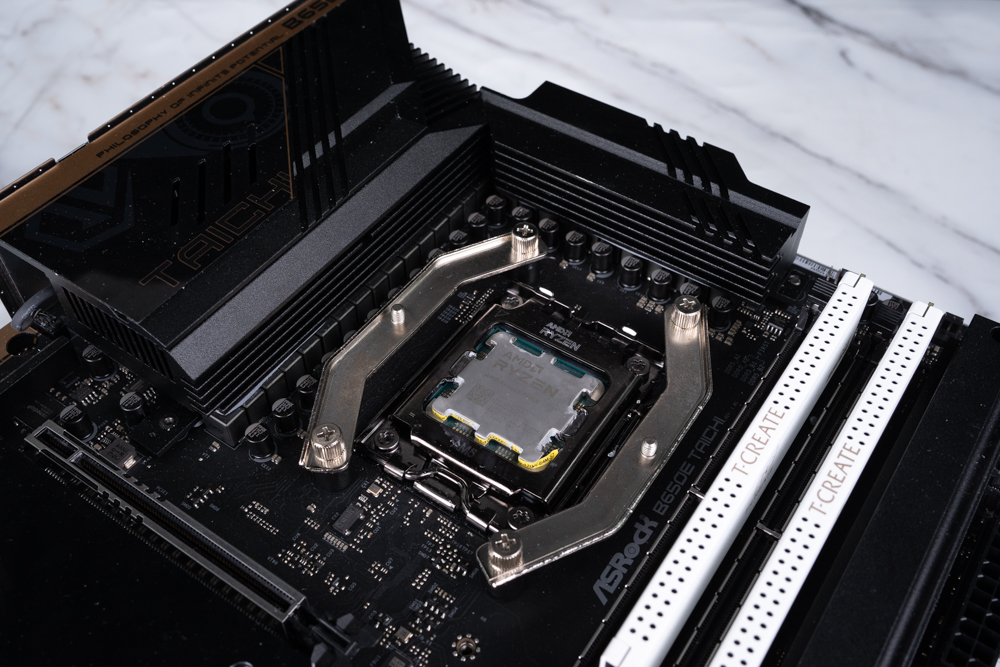

The mounting brackets are properly positioned on the AMD motherboard around the CPU socket, ready for the cooler to be installed. The brackets are lined up with the pre-installed backplate of the motherboard, and the nuts are being used to secure the brackets in place.

These metal brackets are shaped to conform to the specific layout of AMD’s mounting system and are part of the hardware that will support the CPU cooler. The nuts will be tightened to a specified torque to ensure a secure fit without applying excessive pressure that might damage the motherboard.

Once these brackets are securely fastened, the CPU cooler can be mounted on top of them. The cooler will attach to these brackets, which effectively distribute the weight and pressure of the cooler over the CPU for optimal cooling performance. This step is crucial as it ensures that the cooler is not only mounted securely but also aligned correctly for the best thermal contact with the CPU.

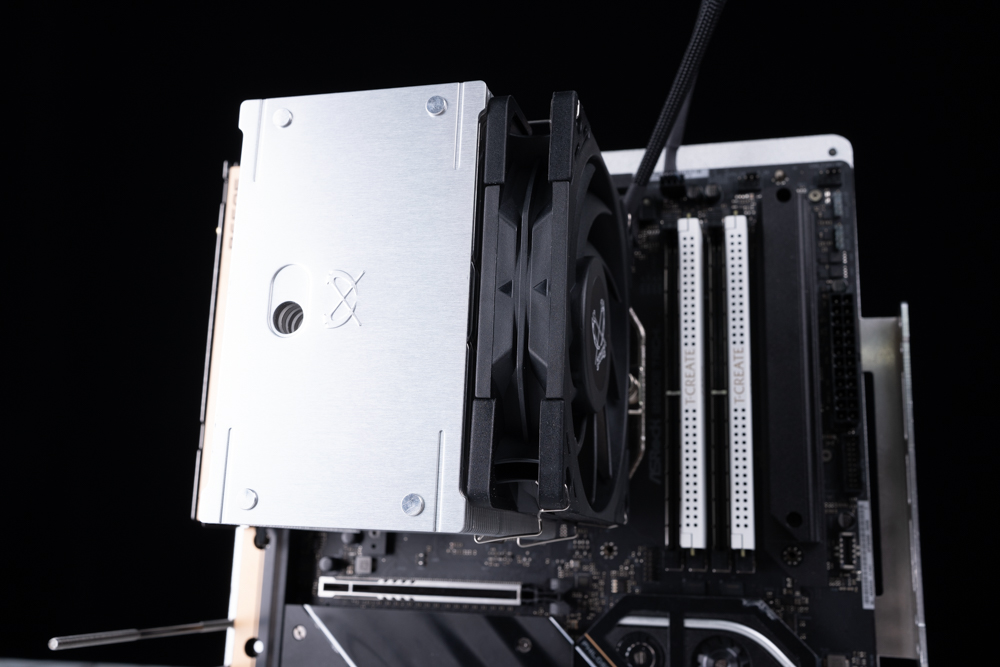

We see the Scythe MUGEN 6 CPU cooler properly installed onto the motherboard. The heat sink is in place, and it appears that the final step of securing the pressure bar with screws is being conducted. The use of a screwdriver to alternately tighten screws at opposite ends ensures an even distribution of pressure, which is crucial for maintaining optimal contact between the CPU and the heat sink for efficient heat transfer.

The heat sink’s top cover provides easy access to the screws with a hole for the screwdriver, allowing for adjustments without the need to remove the entire unit. This thoughtful design facilitates maintenance and adjustments while also maintaining the aesthetic integrity of the cooler.

The cooler’s substantial size and the proximity to the rear I/O panel of the ASRock B650E TAICHI motherboard highlight the importance of checking cooler clearances before installation to ensure compatibility with other components and the computer case. The image showcases a successful installation with the cooler fitting neatly within the confines of the motherboard layout.

The Scythe MUGEN 6 CPU cooler with the fan attached, signifying the completion of the installation process. The fan is positioned to push air through the heatsink fins, facilitating optimal airflow for cooling the CPU. The top cover of the heatsink, featuring the Scythe logo, is visible, indicating that the cooler is ready for operation.

The fan’s wire clips are securely fastened to the heatsink, ensuring that the fan remains stable during operation. These wire clips provide a simple yet effective method for mounting the fan, allowing for easy removal if maintenance or cleaning is necessary.

It’s also evident that there is sufficient clearance between the fan and the RAM modules, which is an important aspect of this cooler’s design, allowing for compatibility with a variety of RAM heights and configurations without impeding installation or airflow.

The image illustrates a successful installation with consideration for component clearance and accessibility, ensuring that the cooler functions efficiently within the system’s build.

Scythe MUGEN 6 Performance Showdown: Intel i9-13900K vs. AMD Ryzen 7-7700 Cooling Efficiency

For comprehensive thermal testing on both Intel and AMD platforms, using high-performance processors like the Intel i9-13900K and the AMD Ryzen 7 7700 is an excellent approach. The testing suite you’ve outlined includes a mix of synthetic benchmarks and real-world gaming scenarios, which should provide a well-rounded profile of the Scythe MUGEN 6’s cooling capabilities.

Here’s a breakdown of the tests:

- AIDA CPU Test: This will push the processor to perform complex calculations, putting a significant load on the CPU and heating it up. Monitoring the temperatures during this test will show how well the cooler handles CPU-specific tasks.

- AIDA FPU Test: The FPU (Floating Point Unit) test is even more intense, focusing on the CPU’s floating-point operations. It’s known to generate more heat, providing a stern test for the cooling solution.

- 3DMARK Fire Strike Ultra: This benchmarking tool is designed to test the performance of computer hardware, primarily the GPU, in graphically intensive tasks. While it is more GPU-focused, it can still provide useful data on CPU heat management under mixed workloads.

- Cyberpunk 2077 Benchmark: As a real-world gaming test, this will simulate the type of load the CPU and GPU would experience during actual gameplay. Since games like Cyberpunk 2077 can create fluctuating loads that more closely mimic everyday use, this test is crucial for users interested in gaming performance.

While running these tests, it’s important to monitor temperatures, clock speeds, and potentially even sound levels to evaluate the cooler’s performance. Factors such as ambient room temperature and case airflow can significantly influence the results, so maintaining consistent testing conditions is essential for accurate comparisons.

The results of these tests will be valuable for anyone looking to understand how the MUGEN 6 performs under various conditions, from maximum CPU stress to typical gaming sessions, on the latest high-end CPUs from both Intel and AMD.

With the provided system specifications for both the Intel and AMD platforms, you have established a solid foundation for conducting thermal performance tests on the Scythe MUGEN 6 CPU cooler.

For the Intel test platform, featuring the high-end Core i9-13900K processor paired with the ASUS Z790 ProArt Wifi motherboard, KLEVV DDR5-6200 memory, and an NVIDIA RTX 4060 Ti, you have a powerful setup that is likely to generate significant heat under load, making it an excellent testbed for the cooler’s capabilities.

Similarly, the AMD test platform is equipped with the AMD Ryzen 7 7700 processor on an ASROCK B650E Taichi motherboard, TEAMGROUP DDR5-6400 memory, and the same NVIDIA RTX 4060 Ti GPU. This setup also promises to be a rigorous test for the MUGEN 6, especially considering the Ryzen 7’s heat profile and performance characteristics.

Both systems are powered by an FSP Hydro Ti Pro 1000W power supply unit, ensuring stable and ample power delivery during testing. The consistency in GPUs across both platforms allows for a controlled comparison in thermal performance directly attributed to the CPU and cooler combination.

Running these systems on Windows 11 Pro 23H2 will also provide a modern operating system environment, which is optimized for the latest hardware and could potentially influence thermal management and efficiency.

When testing, you will likely focus on the following metrics:

- Peak CPU Temperatures: The highest temperatures reached during the most intensive parts of the benchmarks.

- Average CPU Temperatures: More indicative of typical use, this metric is crucial for understanding daily performance.

- Thermal Throttling: Whether or not the CPU needs to lower its clock speed to maintain safe operating temperatures.

- Noise Levels: How loud the cooler’s fan gets during different levels of demand.

- Cooler Efficiency: How quickly the cooler can bring temperatures down after peak loads.

The results of these tests will provide valuable insights into the performance of the Scythe MUGEN 6 CPU cooler in handling the thermal output of the latest CPUs from Intel and AMD. It will also help to determine if the cooler is a viable option for builds intended for high-performance tasks such as gaming, content creation, and intensive computational workloads.

i9-13900k 10-minute temperature test

The temperature results of a 10-minute stress test on an Intel i9-13900K CPU using the Scythe MUGEN 6 (SCMG-6000) cooler in an open test bench setup at a room temperature of approximately 22°C, with BIOS settings at default values.

Here’s a summary of the test outcomes:

- AIDA64 FPU Test: Reached a maximum temperature of 100°C with a power draw of 239W. This test is particularly strenuous as it heavily loads the CPU’s Floating Point Unit, generating a lot of heat.

- AIDA64 CPU Test: Recorded a temperature of 95°C. This test stresses the CPU through various workloads and is slightly less intense than the FPU test.

- 3DMARK Fire Strike Ultra: Achieved a temperature of 48°C. Since this benchmark primarily stresses the GPU, the CPU temperature remains significantly lower.

- Cyberpunk 2077 Gaming: Observed a temperature of 76°C during gameplay, which is a realistic scenario for most users and shows how the cooler performs under typical gaming conditions.

The temperatures recorded during the AIDA64 CPU and FPU tests are at the upper range of what is considered safe for long-term CPU operation, indicating that while the Scythe MUGEN 6 can handle the heat output of the i9-13900K, it’s at the limits of its cooling capacity under extreme load conditions.

The much lower temperatures during the 3DMARK test and Cyberpunk 2077 gameplay suggest that the cooler performs adequately under typical gaming loads, which are less intense than synthetic CPU stress tests.

It’s important to note that reaching 100°C could potentially induce thermal throttling, where the CPU reduces its clock speed to prevent overheating. Prolonged operation at these temperatures is not recommended, as it may impact the longevity of the CPU. However, real-world applications like gaming appear to be well within the cooler’s capability to manage effectively.

These results would be helpful for potential users to understand the cooler’s performance envelope and to set expectations for its operation under various conditions. It also highlights the importance of good case airflow and possibly considering additional cooling solutions or custom fan curves for users planning on pushing their hardware to the limits.

Ryzen 7-7700 Temperature test

The temperature test results for the AMD Ryzen 7 7700 using the Scythe MUGEN 6 (SCMG-6000) cooler show the following:

- AIDA64 FPU Test: The CPU reached a temperature of 95.3°C with a power consumption of 186.81W. This test, much like on the Intel platform, is highly demanding and generates significant heat as it stresses the CPU’s floating-point unit.

- AIDA64 CPU Test: A temperature of 76.4°C was observed, which is considerably lower than the FPU test, indicating good performance under typical CPU workloads.

- 3DMARK Fire Strike Ultra: The temperature recorded was 53.2°C. This benchmark is GPU-centric, and the lower CPU temperature reflects the less intense CPU load during this test.

- Cyberpunk 2077 Gaming: A temperature of 68.3°C was noted during gameplay, which is a realistic thermal load and well within the acceptable range for modern CPUs under gaming conditions.

Comparing these results with the Intel platform, the Scythe MUGEN 6 handles the AMD Ryzen 7 7700 at a slightly lower temperature under maximum load (95.3°C for AMD vs. 100°C for Intel in the AIDA64 FPU Test). This difference could be due to the different architectures and power efficiencies between the two CPUs or the different ways they manage thermal loads.

Overall, the MUGEN 6 cooler performs adequately on the AMD platform, managing to keep temperatures under control even under high stress, though nearing the upper thermal limits during the most intense tests. For daily tasks and gaming, the cooler maintains comfortable temperature margins.

The results affirm that the Scythe MUGEN 6 is a competent cooling solution for the Ryzen 7 7700, capable of sustaining performance under varied loads. Users of high-performance systems can rely on this cooler for their day-to-day computing and gaming needs, though for extreme workload scenarios, considering additional cooling strategies or more robust cooling solutions might be prudent.

Summarize

In conclusion, the SCYTHE MUGEN 6, distributed by Sycom, is available for purchase in two versions: the Standard Edition with a single fan and the Kuro (Black) Twin Fan Edition. Both models are equipped with the 2000 RPM Kaze Maru (Wonder Tornado) 120mm PWM fan, designed to deliver powerful cooling performance with minimal noise. The price difference of TWD 300 between the two models offers users the choice to prioritize aesthetics with the dual-fan version, which could be seen as a reasonable upgrade for those who value visual appeal in their setup.

The offset tower design of the MUGEN 6 ensures compatibility with RAM modules, avoiding any clearance issues, which is a thoughtful consideration for users with high-profile memory sticks. The cooler’s height of only 154mm makes it suitable for a wide range of computer cases, from mid to full-sized towers.

The pricing for the single-fan Standard Edition stands at TWD 1390, making it an affordable option for those seeking efficient cooling. For those desiring the enhanced look and potentially better cooling performance of the dual-fan setup, the Kuro Twin Fan Edition is priced at TWD 1690, representing value for an upgrade in both aesthetics and performance.

The MUGEN 6 series, with its versatility, ease of installation, and efficient cooling performance, caters to a broad audience, from enthusiasts to professional users, who seek reliable thermal management solutions for their high-performance computing needs.

If this article is helpful for you, please share this article with your friends on social media. Thank you!

This article is based on the personality of the reviews. You are responsible for fact-checking if the contents are not facts or accurate.

Title: Maximize Your PC’s Performance: Introducing the SCYTHE MUGEN 6 CPU Cooler with Wonder Tornado Fan