Corsair, a renowned leader in the realm of computer cooling solutions, has once again set sail into the market with its most powerful CPU air cooler to date – the Corsair A115. Launched at the beginning of 2024, this dual-tower CPU air cooler is equipped with two Corsair AF14 ELITE PWM 140mm fans, promising superior cooling performance with ease of installation. The A115 comes pre-applied with XTM70 thermal paste, making it ready for immediate setup straight out of the box. This flagship model stands as the epitome of Corsair’s commitment to delivering high-efficiency cooling solutions.

Specifications:

- Dimensions: 153 x 155 x 164.8mm, ensuring a significant presence in your PC case while designed to fit without interfering with RAM slots.

- Weight: 1.59kg, a testament to its robust build and quality materials.

- Heat Pipe Configuration: Features 6 x 6mm heat pipes, crafted from copper for optimal heat dissipation.

- Base Material: The base is made of nickel-plated copper, enhancing the cooler’s durability and thermal conductivity.

- Fan Quantity: Includes two 140mm x 25mm fans, providing ample airflow to maintain cool CPU temperatures.

- Supported Sockets: Compatible with a wide range of sockets, including Intel 1700, 1200, 1150, 1151, 1155, 1156, and AMD AM5, AM4, making it a versatile choice for various builds.

- Fan Speed: 400 – 1600 RPM ±10%, allowing for customizable cooling performance based on your system’s needs.

- Airflow: 15.3 – 84.5 CFM, ensuring efficient heat removal from the CPU.

- Static Pressure: 0.1 – 1.73 mm-H2O, indicating the fans’ capability to push air through dense heatsinks.

- Noise Level: 5 – 33.9 dBA, balancing cooling efficiency with noise control for a quieter operation.

- Fan Model: AF ELITE PWM 140mm, known for its reliability and performance.

- Bearing Type: FDB (Fluid Dynamic Bearing), offering longer lifespan and quieter operation.

- Fan Control: 4-pin PWM, providing precise control over fan speeds for optimal cooling and acoustics.

- Lighting: No RGB lighting, focusing purely on performance without the distraction of lights.

- Warranty: 5 years, highlighting Corsair’s confidence in the A115’s quality and durability.

Corsair’s A115 CPU air cooler is a top-tier option for enthusiasts seeking maximum cooling efficiency without compromising on ease of installation or compatibility. Its robust build, combined with advanced cooling technology, ensures that your CPU remains at optimal temperatures, even under heavy loads, making it a prime choice for gamers and professionals alike.

Unleash Superior Cooling with Corsair A115: A Dual-Platform Compatible CPU Cooler Featuring Advanced Heat Dissipation Technology

The Corsair A115 CPU air cooler’s retail packaging. The box is prominently Corsair’s signature yellow with a large, clear image of the A115 cooler on the front, reinforcing the brand’s visual identity. The packaging highlights the cooler’s high-performance capability and is marked with the model name “A115,” along with the Corsair logo at the top, ensuring instant brand recognition.

The Corsair A115 is a versatile cooling solution that supports a broad range of installations for both Intel and AMD platforms. It features an efficient thermal system that includes 6 x 6mm copper heat pipes and 90 cooling fins designed to dissipate heat effectively. The contact surface with the CPU is slightly convex to concentrate cooling directly where it’s most needed, optimizing the thermal exchange.

The symmetrical tower design of the A115 not only provides an aesthetic appeal but also incorporates practical considerations such as clearance for memory modules. This attention to design detail allows for easy installation and ensures compatibility with a variety of DRAM configurations. The innovative ratchet mechanism allows for tool-free adjustment of the fan’s height, further enhancing the hardware compatibility with the DRAM modules.

The packaging and product design of the Corsair A115 reflect a thoughtful balance of form and function, aiming to deliver an effective and user-friendly cooling experience while also ensuring compatibility with a wide array of PC components.

The back side of the Corsair A115 CPU air cooler’s packaging provides a multilingual simplified specification table. This table is beneficial for a global customer base, detailing the product’s features and specifications in various languages, ensuring that the information is accessible to a wide audience.

In addition to the specification table, the packaging also includes a visual diagram of the cooler with dimensions, giving potential buyers a clear idea of the size and design of the product, which is crucial for determining compatibility with their PC cases and components.

The back of the box emphasizes several key features of the A115 cooler, such as:

- 6 x 6mm heat pipes for high-efficiency heat transfer.

- Corsair AF14 ELITE PWM fans are equipped with A-fluid dynamic bearing technology for low-noise operation and high airflow.

- Pre-applied XTM70 thermal paste for convenience and a quick installation process.

- Compatibility with a range of CPU sockets from both Intel and AMD, including Intel’s LGA 1700, 1200, 115X series, and AMD’s AM4 platform.

The technical specifications area provides detailed information such as:

- Dimensions: 153 x 155 x 164.8 mm

- Fan configuration: Dual 140mm fans

- Fan speed: 400 – 1600 RPM ±10%

- Airflow: 15.3 – 84.5 CFM

- Static pressure: 0.1 – 1.73 mm-H2O

- Noise level: 5 – 33.9 dBA

This comprehensive presentation of features, specifications, and compatibility ensures that consumers have all the necessary information to make an informed purchase decision. It showcases Corsair’s commitment to transparency and customer satisfaction.

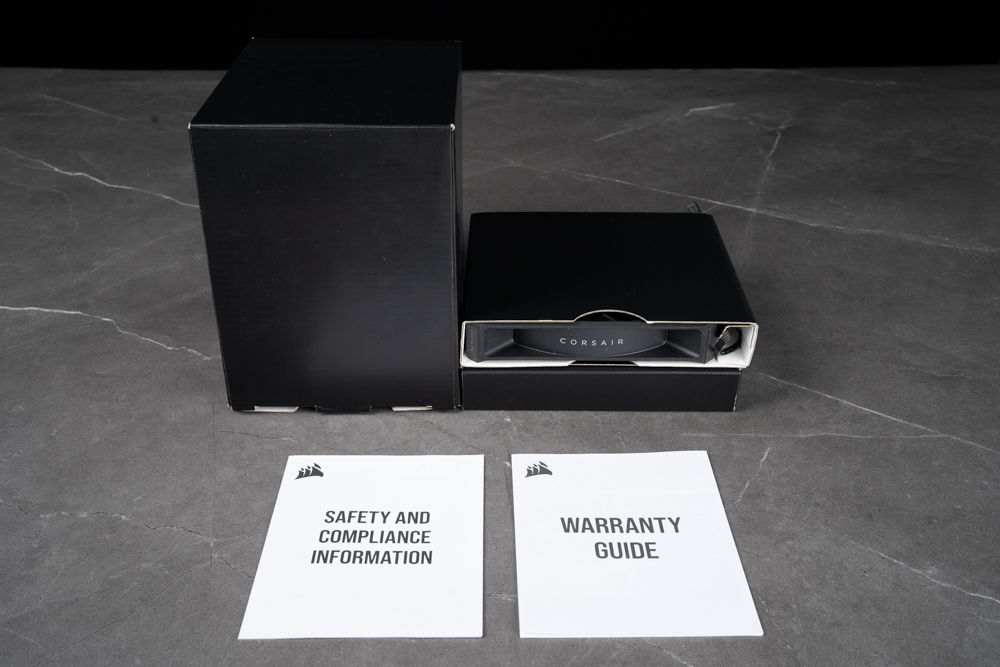

The unboxing of the Corsair A115 CPU air cooler displays the contents typically found within the package. In the foreground, there are two booklets: one for Safety and Compliance Information, and the other is a Warranty Guide, both of which are critical for users to understand the product’s safe usage parameters and warranty details.

In the background, we see the packaging, which is a sleek black box with the Corsair logo prominently displayed on the drawer-like compartment, hinting at a premium and user-friendly unboxing experience. This compartment contains the cooler itself, along with the 140mm fans and a parts package. The parts package would generally include mounting hardware for different CPU sockets, fan clips, and perhaps additional thermal paste or pads.

While the actual cooler and fans are not visible in this image, the inclusion of the instruction manual suggests that Corsair provides comprehensive guidance for installation, ensuring that even users who are less experienced with PC building can install their new cooler with confidence.

The presentation here underscores Corsair’s attention to detail, not only in the product design but also in the packaging and the provision of informative literature to enhance the user experience.

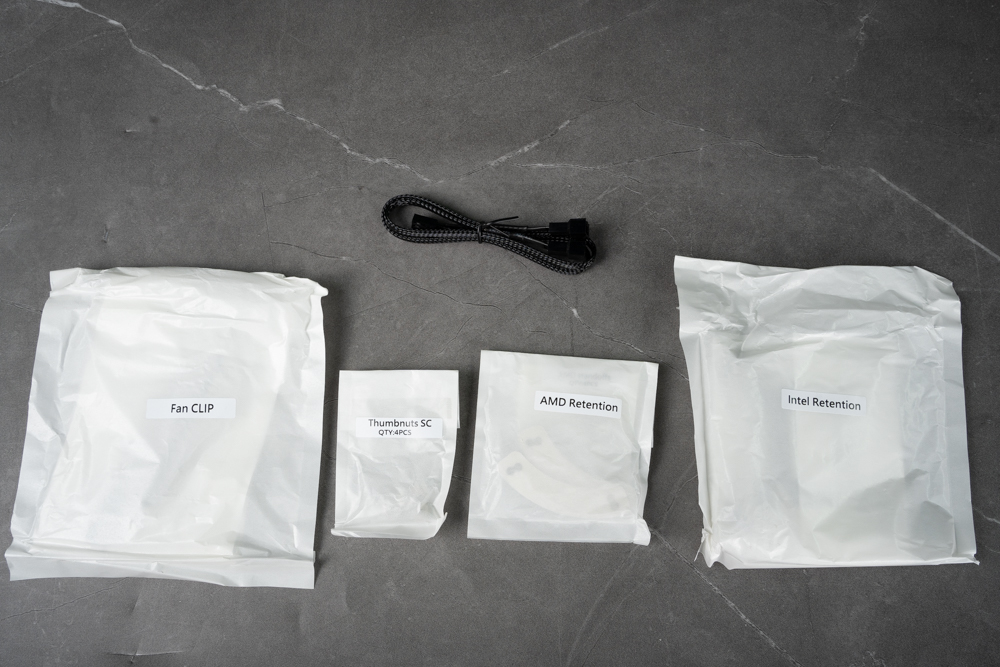

The accessory components that come with the Corsair A115 CPU air cooler. These parts are crucial for the installation and operation of the cooler on different motherboard platforms. Here’s what we see:

- Fan Clip: These are used to attach the cooling fans to the heatsink. There is typically a pair provided for each fan included with the cooler.

- Thumbnuts SC (Screw Caps): Labeled “QTY: 4PCS,” these are the thumbscrews used for securing the cooler to the motherboard without needing additional tools, enhancing the ease of installation.

- AMD Retention: This bag contains the retention brackets and possibly other hardware necessary for mounting the cooler onto an AMD motherboard socket, such as AM4 or the newer AM5.

- Intel Retention: Similarly, this bag holds the retention brackets and hardware for attaching the cooler to Intel motherboard sockets like LGA 1700, 1200, 1150, 1151, 1155, and 1156.

- PWM Y-Split Cable: This is a cable that allows two fans to be connected to a single PWM fan header on the motherboard. This ensures that both fans can be controlled simultaneously for consistent cooling performance while saving space on the motherboard for other connections.

Each of these components is individually packaged, to prevent damage and to make the installation process as straightforward as possible. This attention to detail in packaging individual components separately not only aids in organization but also reflects Corsair’s commitment to customer satisfaction and product reliability.

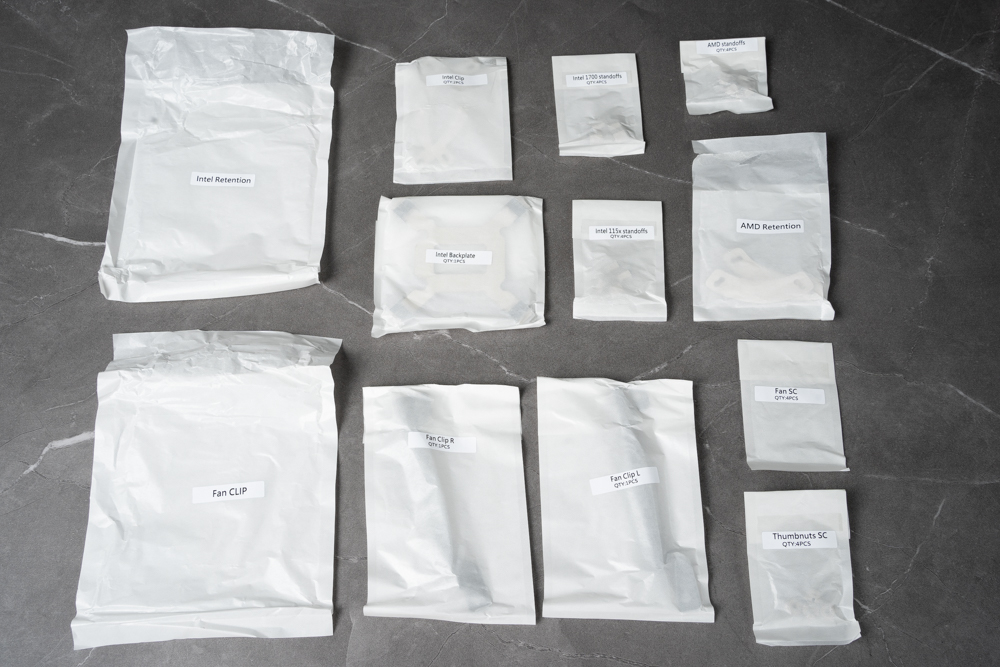

A detailed view of all the labeled accessory bags included with the Corsair A115 CPU air cooler, each component clearly marked for easy identification during the installation process. Here’s an overview of each labeled part and its purpose:

- Intel Retention: This bag contains the mounting hardware required for attaching the cooler to Intel motherboard sockets.

- AMD Retention: This bag holds the mounting hardware necessary for AMD motherboard socket installations.

- Fan Clip: There are two bags labeled “Fan Clip,” which include the clips for securing the fans to the heatsink.

- Intel Backplate: A crucial part of the mounting hardware for Intel sockets, providing stability and support for the cooler.

- AMD Standoffs: These are specifically for AMD installations, providing the necessary spacing and support for the cooler on the motherboard.

- Intel 115X Standoffs: Standoffs for Intel’s 115X series sockets, accommodating various Intel motherboard types.

- Intel 1200 Standoffs: Standoffs are designed for use with the Intel 1200 series socket.

- Fan SC: Possibly screws or connectors for the fan installation.

- Thumbnuts SC: These are thumbscrews for securing the cooler, facilitating a tool-less installation for convenience and ease.

Each bag is a testament to Corsair’s dedication to customer convenience, ensuring that users can easily identify and use the correct parts for their specific CPU socket type. The clear labeling helps prevent confusion during the assembly process, contributing to a smoother building experience for both novice and experienced PC enthusiasts alike.

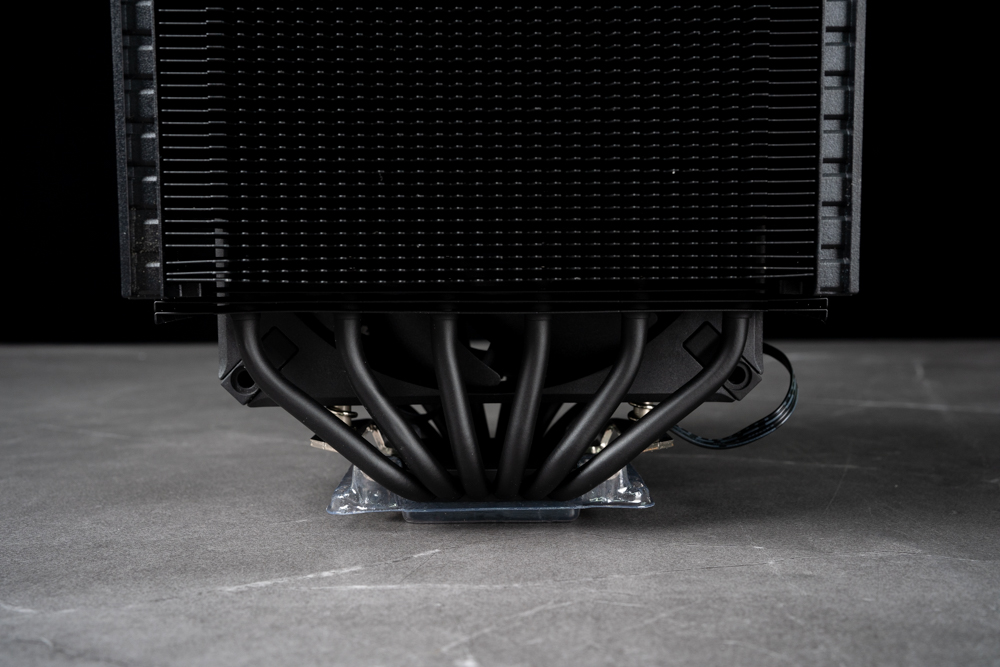

A close-up of the Corsair A115 CPU cooler’s base, where we can see that it comes pre-applied with XTM70 thermal paste, a detail that underscores the user-friendly approach Corsair is known for. The thermal paste is protected by a transparent, specially designed-cover, which ensures the integrity of the pre-applied thermal compound during shipping and handling.

The presence of this protective cover is an excellent addition as it safeguards the thermal paste from being smeared or contaminated before installation, ensuring optimal thermal conductivity when the cooler is mounted onto the CPU.

The image also gives a glimpse of the cooler’s robust construction and design. The black heat pipes and radiator fins are indicative of a sleek aesthetic, which is often preferred by users who are looking for performance along with a visually appealing component that complements their system’s interior. The overall design suggests a focus on high efficiency and durability, which are hallmark traits of Corsair’s cooling products.

The close-up image provides a detailed view of the Corsair A115 CPU cooler’s base, revealing the slightly convex copper base designed for direct contact with the CPU. This convex shape is engineered to ensure maximum contact at the center of the CPU, where heat is most concentrated, thereby enhancing the cooler’s heat dissipation efficiency.

The copper base has undergone nickel plating, a treatment that serves multiple purposes. Firstly, it prevents the copper from oxidizing, which can lead to a deterioration in thermal performance over time. Secondly, nickel plating creates a smoother surface that can improve the spread of thermal paste and heat transfer.

The pre-applied XTM70 high-quality thermal paste visible on the base is a thoughtful touch. This paste is a high-conductivity compound chosen for its ability to fill even the smallest imperfections on the CPU’s IHS (Integrated Heat Spreader), ensuring optimal heat transfer from the CPU to the cooler.

The overall design and manufacturing of the A115’s base reflect Corsair’s dedication to quality and performance, with attention to detail that can contribute significantly to the longevity and effectiveness of the cooling solution.

A side view of the Corsair A115 CPU air cooler, focusing on the dual-tower design. Between the two towers of fins, a cardboard spacer is inserted to maintain the proper distance between them. This spacer plays a crucial role in preserving the integrity of the cooler during transit by preventing the fins from bending or damaging each other if the package is jostled or compressed.

This level of precaution is indicative of Corsair’s commitment to quality assurance and customer satisfaction. By ensuring that the cooler arrives in pristine condition, they minimize the risk of potential performance issues that could arise from bent fins, which can impede airflow and reduce cooling efficiency.

The cardboard spacer also demonstrates Corsair’s attention to detail in packaging, which is an often overlooked aspect of product design but critical to the user experience. It ensures that the end-user receives the cooler in the best possible condition, ready for installation without the need for any corrective measures.

The front view of the Corsair A115 CPU air cooler showcases its robust dual-tower design. The two large arrays of black fins are designed to maximize the surface area for heat dissipation. Between these towers is a central fan, one of the Corsair AF14 ELITE PWM 140mm fans, strategically placed to push air through both sets of fins for optimal cooling.

The branding is visible on the shroud that covers the fan, with the “CORSAIR” logo prominently displayed in white, contrasting with the cooler’s black color scheme. This not only serves as a bold aesthetic feature but also reinforces the brand identity.

At the base of the cooler, we can see the heat pipes curving up into the fin stacks. These heat pipes are critical for transferring heat away from the CPU and into the fins where it can be dissipated by the airflow from the fan.

The cooler is also still equipped with the protective cover on the base, indicating it is new and has not yet been installed. This level of detail in the presentation of the product highlights Corsair’s commitment to delivering a high-quality, visually appealing, and performance-driven cooling solution for PC enthusiasts and professionals.

A bottom-up perspective of the Corsair A115 CPU air cooler, focusing on the base where six 6mm copper heat pipes are visible. These heat pipes are a critical component of the cooler’s design, as they are responsible for conducting heat away from the CPU and distributing it evenly throughout the fin stacks for dissipation.

The heat pipes are arranged to extend through the base and up into both towers of fins, ensuring that heat is spread efficiently across the entire cooling structure. The arrangement and size of these pipes are optimized to handle high thermal loads, which is crucial for maintaining CPU performance during demanding tasks or overclocking scenarios.

The protective plastic cover is still attached to the base, which safeguards the pre-applied thermal paste and the delicate surface of the copper base until the cooler is ready to be installed. This protective measure ensures that the thermal interface remains clean and intact, providing the best possible thermal transfer when the cooler is mounted onto a CPU.

The craftsmanship of the heat pipes, along with the overall build quality visible in the image, highlights Corsair’s commitment to providing high-performance cooling solutions for gaming rigs, workstations, and any system where maintaining optimal CPU temperatures is vital.

We see the Corsair A115 CPU air cooler’s heat sink side by side with an unassembled 140mm fan, presumably one of the Corsair AF14 ELITE PWM fans that are part of the cooler’s package. The heat sink features a dense array of black fins which are responsible for dissipating heat. The black color scheme of both the heat sink and the fan creates a sleek and uniform aesthetic that is often favored in custom PC builds.

The fan itself has a prominent Corsair logo in the center, and its design suggests that it is optimized for high airflow and static pressure, which is essential for pushing air through the dense fins of the heat sink for effective cooling. The PWM (Pulse Width Modulation) capability of the fan allows for precise speed control via the motherboard, enabling dynamic speed adjustments based on CPU temperature and workload.

The four-pin connector cable attached to the fan is a standard for PWM fans, allowing for variable speed control and more efficient power usage compared to three-pin fans. The ability to adjust the fan speed is crucial for balancing cooling performance with noise levels, ensuring that the system can remain quiet under low loads and ramp up cooling when necessary.

The attention to design details in both the heat sink and fan, as well as their potential performance benefits, reflects Corsair’s commitment to quality and the needs of high-performance computing enthusiasts.

The ratchet mechanism fan brackets and screws are included with the Corsair A115 CPU air cooler. These brackets are designed to hold the Corsair AF140 ELITE PWM 140mm fans in place, facilitating a tool-free installation and adjustment process. The ratchet mechanism allows for easy height adjustment of the fans, ensuring that they do not interfere with the memory modules (DRAM), thereby enhancing the hardware compatibility of the cooler.

The fan brackets are labeled with “L” for the left side and “R” for the right side, simplifying the assembly process and ensuring that each bracket is used on the correct side. The screws shown are used to secure the brackets to the cooler.

The inclusion of the ratchet mechanism for fan installation is a thoughtful design choice that underscores Corsair’s commitment to a user-friendly experience. It allows for quick and easy adjustments, which can be particularly beneficial during the initial build or when upgrading components. The seamless integration of these features with the cooler’s overall sleek matte black finish not only enhances the aesthetic appeal but also speaks to the practicality and ease of use that Corsair aims to deliver with its products.

The 140mm CORSAIR AF140 ELITE PWM fan, is part of the Corsair A115 CPU cooler package. The fan is mounted onto the ratchet mechanism brackets, ready to be attached to the heat sink. These brackets are designed to snap onto the heat sink without the need for tools, making the installation process simpler and more convenient.

The fan features a four-pin connector cable for PWM control. PWM allows for dynamic speed adjustment based on system performance needs and thermal loads, which helps maintain an optimal balance between cooling efficiency and noise levels. The fan’s design, with its large blades and the Corsair sail logo at the center, is engineered to deliver high airflow and static pressure, essential for pushing air through the dense fins of the CPU cooler.

The barcode and serial number on the fan’s sticker are typically used for inventory and quality control purposes, ensuring that each component can be traced back to its manufacturing batch. This level of traceability is part of Corsair’s quality assurance process.

The image highlights the quality, attention to detail, and user-friendly features of the Corsair cooling solutions, designed to meet the requirements of users looking for performance and ease of installation in their PC cooling systems.

A frontal view of a 140mm PWM fan, featuring nine blades, which is part of the Corsair A115 CPU cooler setup. The fan’s design, characterized by its large, sweeping blades, is optimized to deliver a strong airflow while maintaining low noise levels, which is essential for effective cooling in high-performance computers.

PWM, or Pulse Width Modulation, allows for precise control over the fan’s speed, enabling it to run at exactly the needed RPM to keep the CPU cool, without causing unnecessary noise. The four-pin connector visible in the image is standard for PWM fans, as it communicates with the motherboard to adjust the fan speed based on temperature readings from the CPU.

The Corsair logo in the center of the fan acts as a hallmark of quality and brand recognition. The matte black finish of the fan complements a wide range of computer case aesthetics, appealing to users who prefer a sleek, professional look in their PC builds.

The fan’s design is a testament to Corsair’s commitment to combining performance with style, ensuring that this essential component of the cooling system contributes both functionally and visually to the user’s computing experience.

A close-up of a hand holding two 4-pin PWM fan connectors, which are typically used for connecting case or CPU cooler fans to the motherboard. These connectors allow the fans to be controlled by the motherboard’s PWM function, which can adjust the fan speed dynamically based on the CPU temperature or system cooling requirements.

The flat, ribbon-style cables seen here are designed to minimize clutter and improve airflow within the computer case. The flat design also makes cable management easier, allowing for a neater build and enhancing the overall aesthetics of the system’s interior.

These connectors are key for optimizing cooling efficiency and noise levels, as the PWM control enables the fans to run slower when the system is cool and ramp up only when necessary. This intelligent speed control is vital for maintaining an optimal balance between cooling performance and acoustics in modern computers.

Effortless Installation Guide for Corsair A115: Maximizing Cooling Efficiency on Intel and AMD Platforms

The mounting hardware for an Intel CPU cooler, is specifically designed for the LGA 1700 and 115x socket types. Displayed are:

The backside of a motherboard with an Intel platform backplate is already secured in place. This backplate is an essential part of the mounting system for the CPU cooler, providing a stable and durable anchor point for the cooler’s installation.

The installation process typically involves attaching this backplate to the back of the motherboard and aligning it with the CPU socket’s mounting holes. After the backplate is in place, the corresponding front-side mounting hardware and screws are installed to firmly secure the CPU cooler. It’s recommended to not install the second 140mm fan until after the cooler is securely mounted, as this allows better access to the mounting screws.

According to the instructions, for the Corsair A115 CPU cooler, after securing the cooler with the pre-applied thermal paste on its base, the second fan can then be slid into position along the ratchet mechanism tracks. This allows for a tool-free installation and adjustment of the fan height for optimal memory (DRAM) clearance.

The A115 supports the option to add a third fan for enthusiasts looking to maximize cooling performance. This is facilitated by an extra set of fan brackets, which, as per the user’s description, are already pre-installed on one side of the heat sink, making the addition of an extra fan a straightforward process. This level of customization is indicative of Corsair’s dedication to versatility and performance in their cooling solutions.

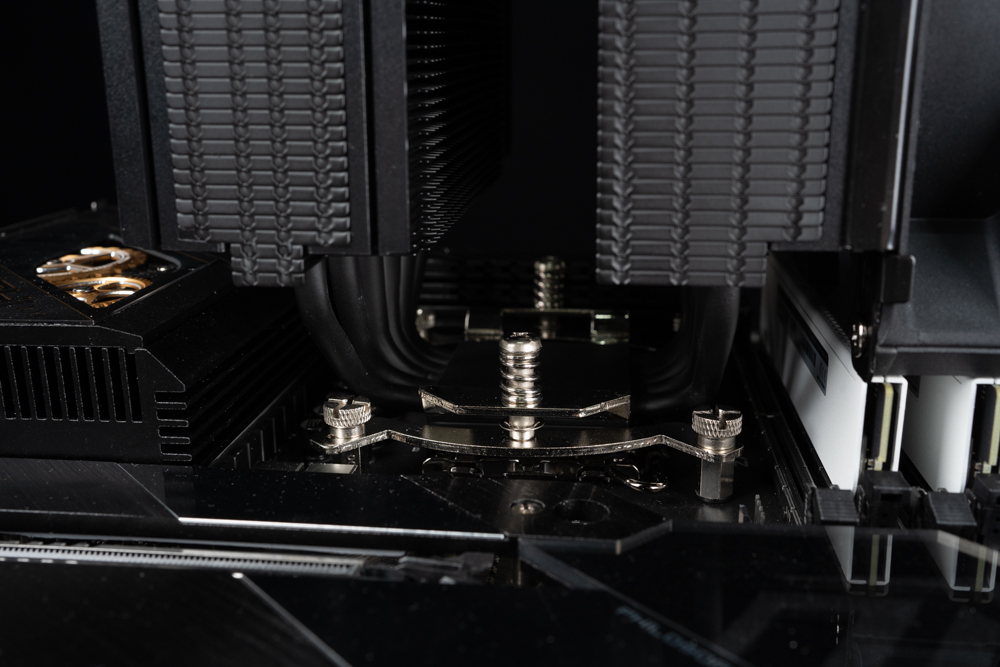

A close-up view of a CPU socket on an Intel motherboard, with the front-side mounting bracket in place and secured with four screws. This bracket is part of the installation process for a CPU cooler, which in this context is for the Corsair A115 mentioned earlier.

The CPU socket is shown with the retention arm raised, ready to receive a CPU. Around the socket, the mounting bracket has been installed with screws at four corners, ensuring a stable and even mounting pressure for the cooler once it’s placed over the CPU.

To the right, we see RAM modules installed in the motherboard’s DIMM slots, indicating the system is either fully assembled or in the process of being built. The placement of the bracket and the visible clearance around the socket suggest that the cooler design accommodates large memory modules without interference, a thoughtful consideration for users who may opt for high-profile RAM.

This stage is crucial as it ensures that the cooler will be properly aligned and secured, providing optimal thermal contact with the CPU. The precision in this step of the assembly is important for the cooler’s performance, and the detailed view here highlights the meticulous nature of PC building.

A close-up view of a CPU cooler’s mounting system installed on a motherboard. The mounting bracket has been securely fixed in place with screws, and the spring-loaded screws in the center suggest that the system is ready for the cooler to be mounted directly on top.

The spring-loaded mechanism on the screws is designed to provide even pressure distribution when the cooler is installed, which is essential for maintaining optimal contact between the CPU and the cooler’s base. This ensures efficient heat transfer and cooling performance.

With the mounting hardware fully installed, the next step in the assembly process would be to place the Corsair A115 cooler onto these brackets, aligning it with the screws, and then securing it in place, typically by tightening the screws in a cross pattern to maintain equal pressure.

The design shown here allows for a straightforward installation process, making it accessible even for those who may be new to PC building. This user-friendly approach to hardware design is often a key consideration for consumers when selecting components for their systems.

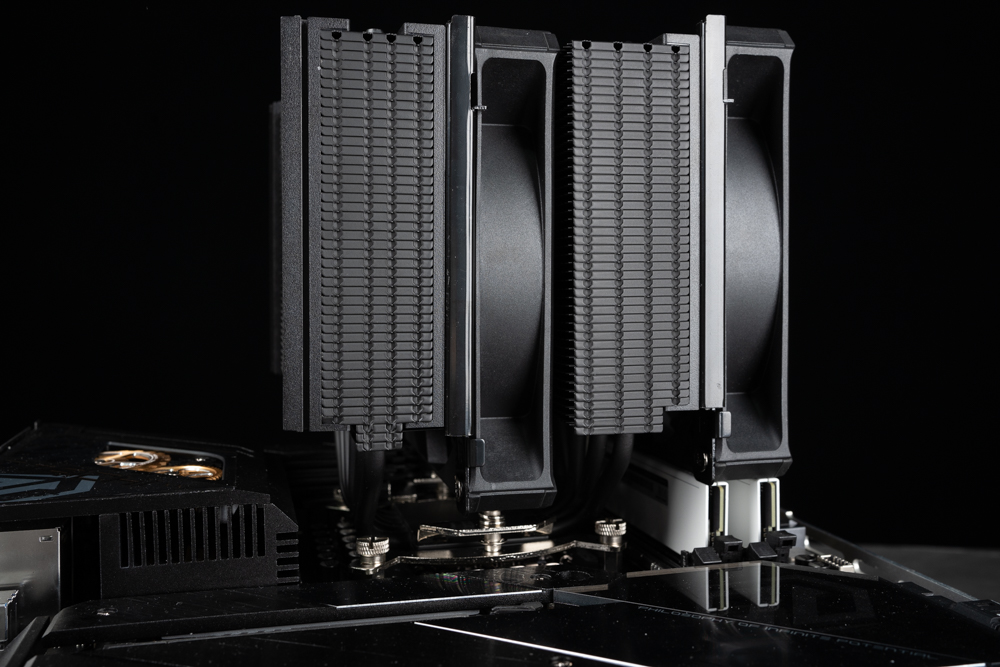

The Corsair A115 CPU cooler is installed on a motherboard, showcasing the ratchet mechanism that facilitates the adjustment of the front fan’s height. This feature is particularly beneficial for ensuring compatibility with high-profile memory modules (DRAM).

With the ratchet mechanism fan brackets, users can slide the fan up or down to the desired height, providing enough clearance to accommodate memory sticks that are up to approximately 32mm in height. This design consideration is critical for those who have large heatspreaders on their RAM modules and need to avoid any potential interference with the cooling tower.

This tool-free adjustment system is a testament to the ingenuity behind the Corsair A115’s design. It not only simplifies the installation process but also provides users with the flexibility to configure their cooling system to best fit the specifics of their build. The ease of adjustability, without the need for tools, enhances the overall user experience and is a welcomed feature for PC enthusiasts who prioritize both aesthetics and functionality in their setups.

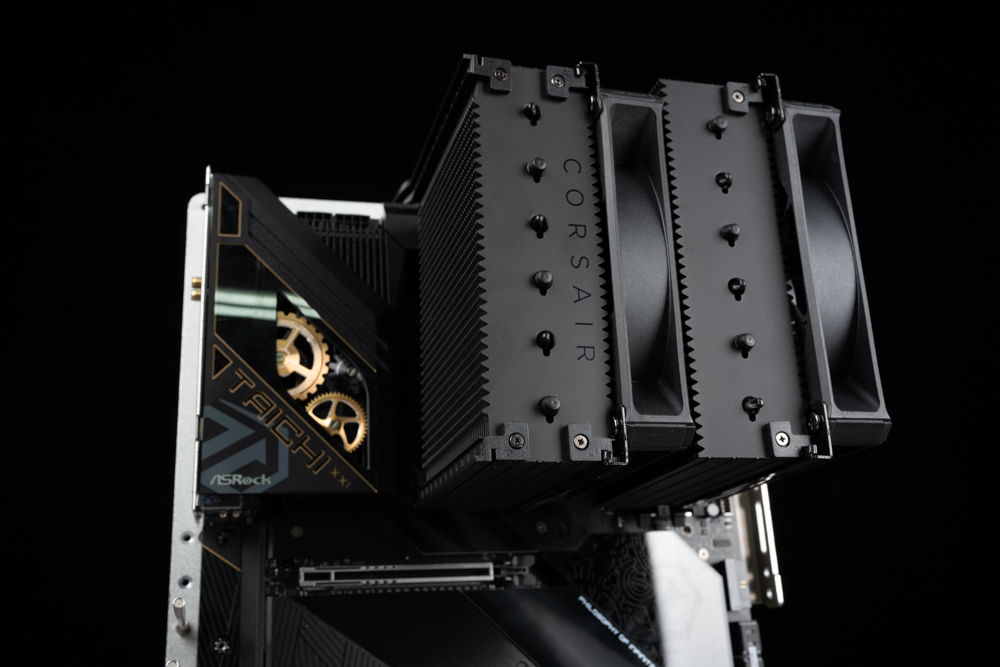

An elevated angle view of the Corsair A115 CPU cooler installed on a motherboard, provides a clear view of its dual-tower heatsink and two mounted fans. The prominent “CORSAIR” branding on the side of the heatsink reinforces the brand’s visual identity, and the uniform black color scheme contributes to a sleek and cohesive aesthetic within the build.

This angle gives a perspective of how the cooler aligns with the motherboard, highlighting the size of the cooler in relation to the motherboard’s form factor. The cooler’s vertical stature is indicative of its high-performance design, aimed at efficiently dissipating heat through the large surface area of the fins.

The fans are positioned to push and pull air through the fins of the heatsink, optimizing airflow for maximum cooling efficiency. The mounting of the cooler appears to be secure and flush against the CPU, which is critical for effective heat transfer.

The careful integration of the cooler with the motherboard, without any visible obstructions or interference with other components, showcases the compatibility and thoughtful engineering behind the product design. It’s also noteworthy how the cooler complements the motherboard’s aesthetics, enhancing the overall visual appeal of the system, which is often an important consideration for PC enthusiasts and builders.

A side perspective of the Corsair A115 CPU cooler mounted on a motherboard, with a focus on the fan and heatsink assembly. The large, central 140mm fan is prominently displayed, situated between two fin stacks of the dual-tower heatsink. The Corsair logo is visible at the center of the fan, serving as a stamp of brand identity.

From this angle, we can observe the depth of the fin stacks, which is indicative of the cooler’s capacity for heat dissipation. The fan is engineered to facilitate air movement through these fins, pulling heat away from the CPU. The design of the fan blades is typically optimized to balance airflow and static pressure, ensuring that air effectively penetrates the fin arrays for optimal cooling performance.

The heatsink’s fin edges appear to be serrated or notched, which could potentially be a design feature to increase air turbulence and improve heat exchange. The precise and uniform spacing between the fins is crucial for maximizing airflow while minimizing resistance.

The image also allows us to appreciate the cooler’s overall build quality and the meticulous attention to detail, characteristics that are often associated with Corsair’s products. The cooler’s assembly with the motherboard looks seamless and well-integrated, suggesting a straightforward installation process and compatibility with the motherboard’s layout.

A side perspective of the Corsair A115 CPU cooler mounted on a motherboard, with a focus on the fan and heatsink assembly. The large, central 140mm fan is prominently displayed, situated between two fin stacks of the dual-tower heatsink. The Corsair logo is visible at the center of the fan, serving as a stamp of brand identity.

From this angle, we can observe the depth of the fin stacks, which is indicative of the cooler’s capacity for heat dissipation. The fan is engineered to facilitate air movement through these fins, pulling heat away from the CPU. The design of the fan blades is typically optimized to balance airflow and static pressure, ensuring that air effectively penetrates the fin arrays for optimal cooling performance.

The heatsink’s fin edges appear to be serrated or notched, which could potentially be a design feature to increase air turbulence and improve heat exchange. The precise and uniform spacing between the fins is crucial for maximizing airflow while minimizing resistance.

The image also allows us to appreciate the cooler’s overall build quality and the meticulous attention to detail, characteristics that are often associated with Corsair’s products. The cooler’s assembly with the motherboard looks seamless and well-integrated, suggesting a straightforward installation process and compatibility with the motherboard’s layout.

A top view of an AMD Ryzen CPU installed in its socket on an ASRock B550 motherboard. The CPU is securely held in place with a retention bracket, and around it, the four mounting points have been prepared for the installation of a CPU cooler, with the screws in place for the cooler’s brackets to attach.

For AMD installations, especially on AM4 sockets as indicated by the “AM5” marking on the motherboard, the original backplate is often used in conjunction with the cooler’s provided standoffs or mounting posts. The standoffs screw into the backplate, providing a foundation to which the cooler’s brackets will be affixed.

This preparation is essential for ensuring that the CPU cooler will be mounted correctly, enabling it to provide optimal cooling efficiency. The process involves removing any pre-installed mounting hardware that comes with the motherboard and replacing it with the hardware provided with the cooler, as this ensures compatibility with the cooler’s specific design.

The visible RAM modules, labeled “T-CREATE,” suggest a focus on a build that may be geared towards creators or users who need high-performance memory for tasks like content creation, illustrating the versatility of the motherboard to cater to various user needs. The careful installation of the CPU and preparation for the cooler installation reflects the precision required to ensure proper thermal management within the system.

We see an AMD Ryzen CPU installed on an ASRock B550 motherboard with a cooling bracket placed over it. This bracket is part of a mounting system for a CPU air cooler, designed to hold the cooler in place over the CPU for effective heat dissipation.

The metal bracket, which forms a cross shape over the CPU, is positioned to align with the mounting points on the motherboard. This bracket will be used to secure the heatsink of the CPU cooler. The mounting points have threaded standoffs installed, which are part of the cooler’s mounting hardware. These standoffs provide the anchor points for the screws that will hold the CPU cooler in place.

The presence of the bracket indicates that the next step will be to place the heatsink on top of the CPU, ensuring that the thermal interface material (TIM) or thermal paste is applied properly for efficient thermal transfer. The heatsink will then be secured by fastening it to the bracket with screws.

The process shown reflects the attention to detail required in PC assembly to ensure optimal performance and cooling efficiency. Proper installation of the CPU cooler is crucial as it directly affects the CPU’s operating temperatures and overall system stability.

The installation of the second set of fans into the Corsair A115 CPU air cooler. The fans slide into place along the ratchet slide rails, part of the cooler’s innovative design that allows for tool-free fan height adjustment. This feature enables easy compatibility with varying sizes of DRAM modules, allowing users to customize the positioning of the fan to either provide more clearance for tall RAM sticks or to optimize airflow within the case.

In this setup, one fan is already installed in the middle of the dual-tower heatsink, and the second fan is being added to the outside, which will operate in a push-pull configuration—where one fan pushes air into the heatsink and the other pulls air out—maximizing the cooling efficiency of the heatsink.

The ratchet mechanism ensures that the fan is securely fastened to the heatsink without the need for additional tools, simplifying the installation process and making future adjustments or maintenance more convenient. This thoughtful design is a hallmark of Corsair’s commitment to user-friendly and high-performance PC components.

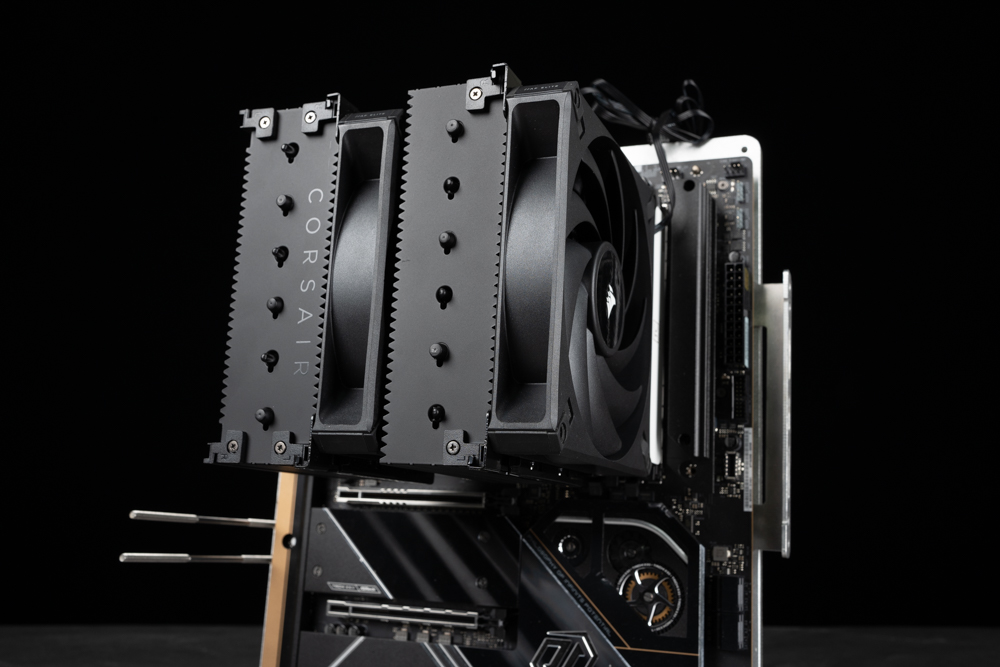

The image displays a completed installation of the Corsair A115 CPU air cooler on an AMD platform motherboard. The cooler is shown with both sets of fans mounted, which suggests a push-pull configuration for optimal airflow through the heatsink’s fins, enhancing the cooler’s ability to dissipate heat from the CPU.

The prominent “CORSAIR” branding on the side of the heatsink fins is visible, reinforcing the company’s branding. The cooler is securely attached to the motherboard, with the mounting system’s screws and brackets indicating a successful installation.

This cooler setup is particularly beneficial for high-performance computing tasks that generate significant heat, such as gaming, video editing, or running intensive applications. The push-pull fan setup is a strategic choice for ensuring that the CPU remains at a stable temperature, even under load, which is crucial for maintaining the performance and longevity of the system.

The image also gives a glimpse of the overall build’s aesthetic, which appears clean and well-organized. Proper installation of a CPU cooler is essential for system stability, and the image demonstrates a meticulous and correct installation process, showcasing the quality and compatibility of Corsair’s cooling solutions with different CPU platforms.

Corsair A115 Dual-Fan Tower Cooler: Benchmarking High-Performance Cooling on Intel and AMD Setups

The Corsair A115 is a high-end CPU air cooler with a dual-tower, dual-fan, 6-heat pipe configuration, designed for enthusiasts seeking substantial cooling capabilities for high-performance CPUs. The specifications provided outline the components for two separate testing platforms, one using an Intel processor and the other an AMD processor.

Intel Test Platform:

- Processor: Intel Core i9-12900K

- Cooler: Corsair A115

- Motherboard: ASRock Z790 Taichi

- Memory: Teamgroup DDR5-6400 16GB x2

- Graphics Card: Nvidia RTX 4060 Ti

- Operating System: Windows 11 Pro 22H2

- Power Supply: FSP Hydro Ti Pro 1000W

AMD Test Platform:

- Processor: Ryzen 7 7700

- Cooler: Corsair A115

- Motherboard: ASRock B650E Taichi

- Memory: Teamgroup DDR5-6400 16GB x2

- Graphics Card: Nvidia RTX 4060 Ti

- Operating System: Windows 11 Pro 22H2

- Power Supply: FSP Hydro Ti Pro 1000W

Testing was conducted in an open bench setup at approximately 21°C ambient temperature, which is ideal for ensuring that external factors minimally influence the CPU’s thermal performance. The tests involved running stress tests and daily gaming scenarios, with benchmarks including AIDA64 FPU, AIDA64 CPU, 3DMARK Fire Strike Ultra, and the Cyberpunk 2077 benchmark.

On the Intel platform, the results showed that under extreme load in AIDA64 FPU, temperatures remained below 90°C, indicating that the Corsair A115 can handle the top-end heat output of the i9-12900K. The AIDA64 CPU temperature of 62°C and the 3DMARK Fire Strike Ultra gaming simulation temperature of 44°C demonstrate the cooler’s efficiency under gaming loads. The Cyberpunk 2077 gameplay temperature of 57°C reflects a balanced performance for daily gaming.

The AMD platform also reported impressive cooling performance, with AIDA64 FPU averaging 66.4°C and AIDA64 CPU at 59.3°C. The 3DMARK Fire Strike Ultra recorded a temperature of 42.4°C, while the Cyberpunk 2077 gameplay temperature was 56.8°C.

These test results confirm the Corsair A115’s capability to provide excellent cooling across different workloads and platforms, making it a reliable choice for users who demand high cooling performance for their high-powered CPUs in both work and play scenarios.

Corsair A115 Sets Sail: A Premier Dual-Platform CPU Cooler with Unmatched Versatility and Performance

Corsair’s impressive debut of the A115 air cooler early in 2024 demonstrates their strong commitment to maintaining a competitive edge in the cooling market. The A115 stands out with its performance, matching and sometimes surpassing its contemporaries, and it’s clear to see why it was eagerly released to make its mark.

The innovative ratchet mechanism of the fan brackets is a notable feature, allowing for flexible adjustments to accommodate various heights of RAM and motherboard heatsinks, ensuring optimal compatibility and ease of installation. This adaptability, coupled with its broad support for multiple CPU socket types, including future support for Intel’s LGA 1851 socket, highlights the A115’s versatility.

The dual CORSAIR AF14 ELITE PWM fans are engineered to balance airflow and noise, with an official noise level cap of 33.9 dBA. In practice, when enclosed within a case, the noise from the fans is likely to be significantly reduced, potentially becoming imperceptible in a typical room environment.

For enthusiasts who demand high thermal performance for high-power CPUs, as well as those with lower-power processors seeking efficient temperature control, the Corsair A115 is an excellent choice. Its market launch on January 16th at a price point of approximately 3000 TWD positions the A115 as a strong contender among similarly priced competitors in the air cooling category.

For DIY builders looking to upgrade their PCs, perhaps using the financial boost from New Year’s red envelopes, the Corsair A115 is a noteworthy option to consider. It offers a blend of high-end cooling capabilities, aesthetic appeal, and user-friendly features that are attractive to those looking to enhance their system’s performance and appearance.

If this article is helpful for you, please share this article with your friends on social media. Thank you!

This article is based on the personality of the reviews. You are responsible for fact-checking if the contents are not facts or accurate.

Title: Corsair Unveils A115: The Ultimate Dual-Tower CPU Cooler for High-Performance Cooling in 2024